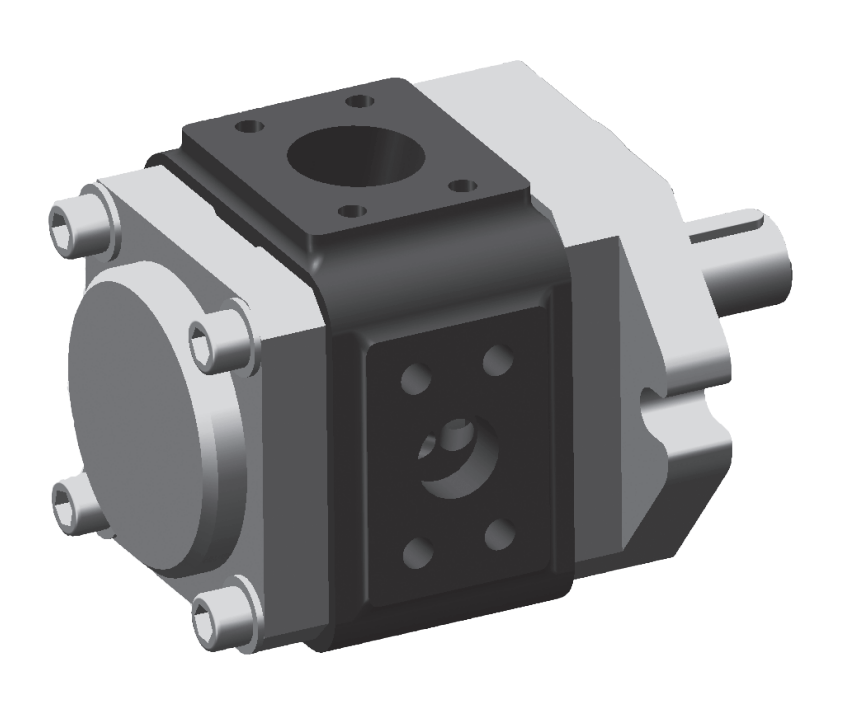

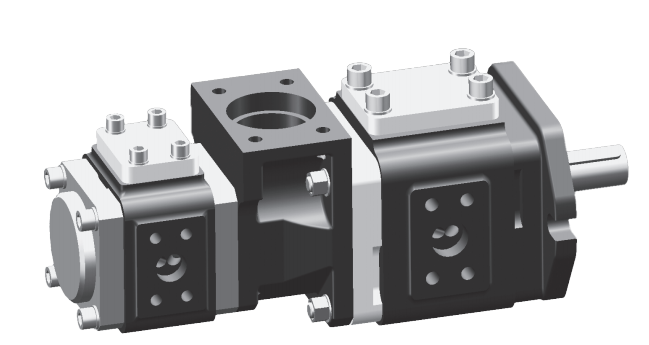

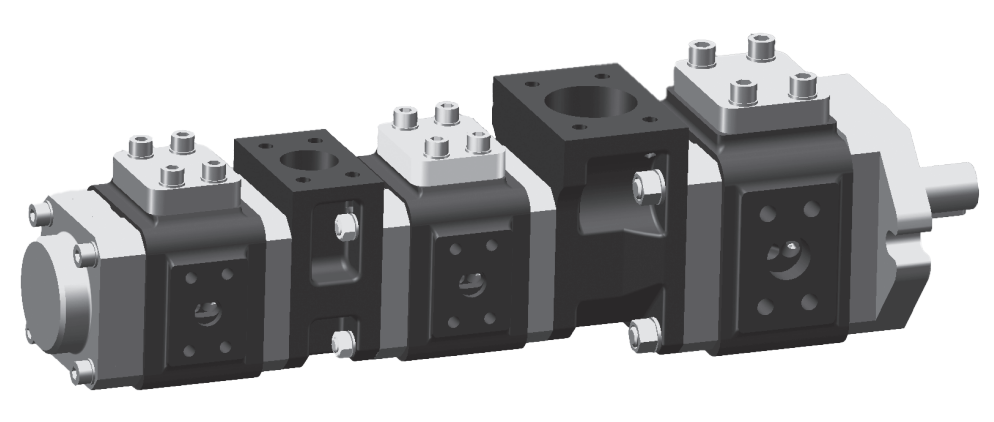

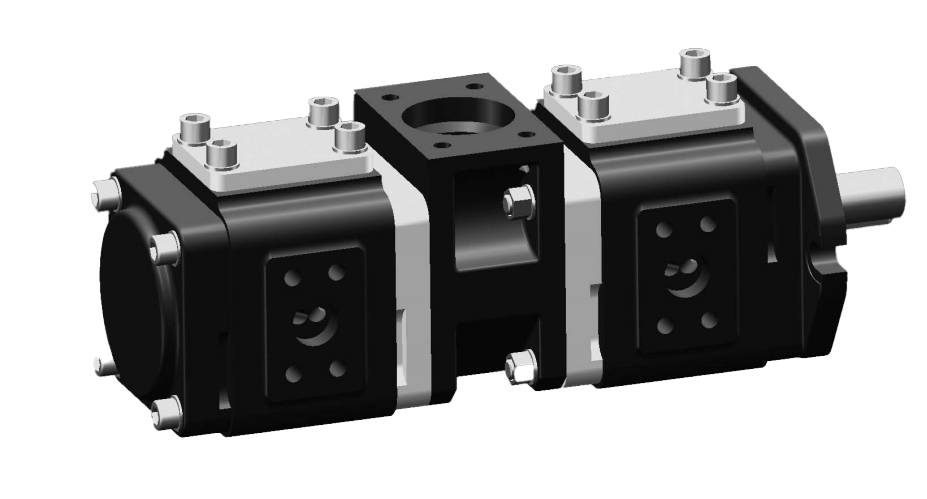

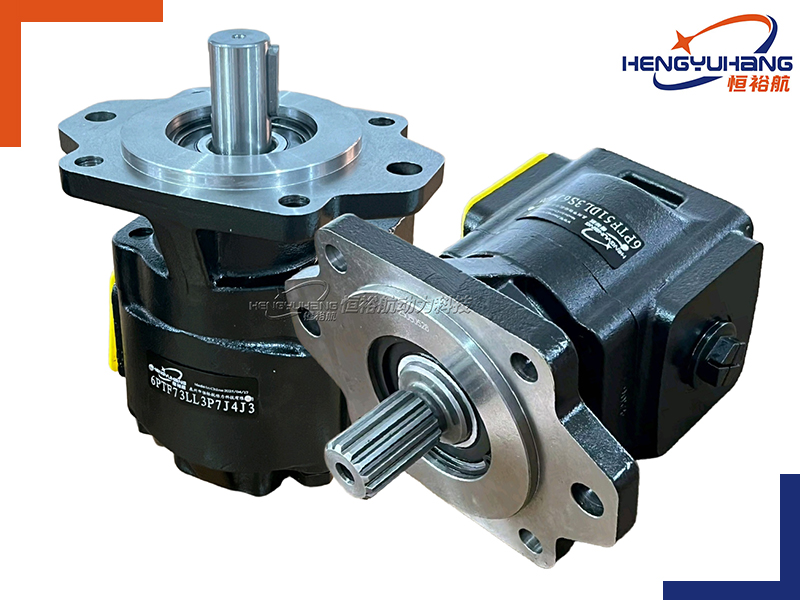

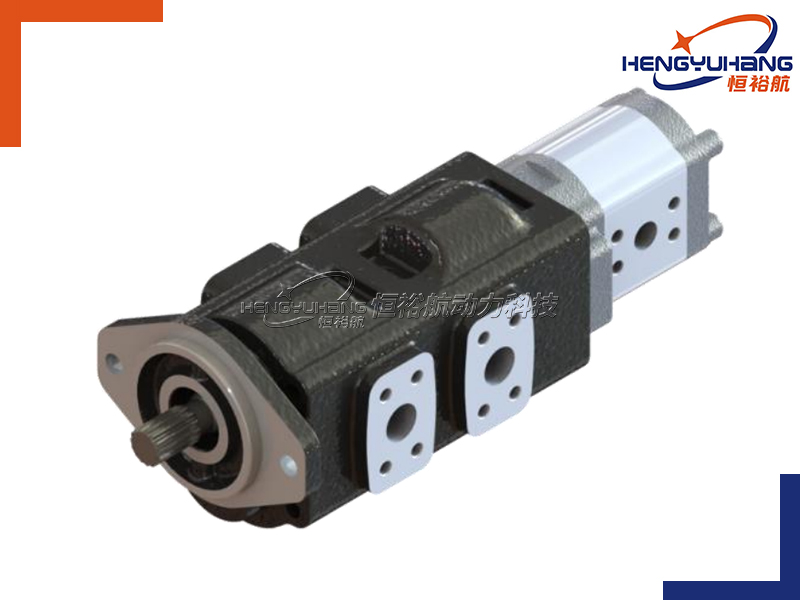

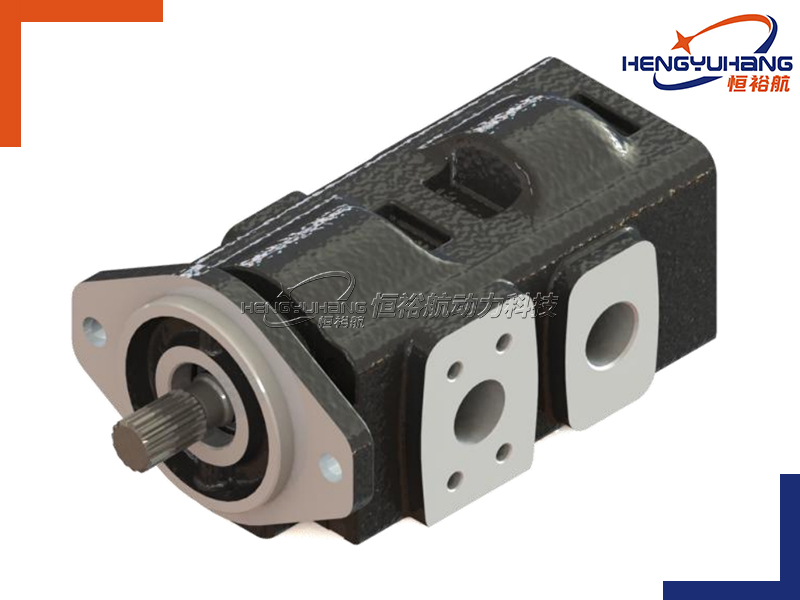

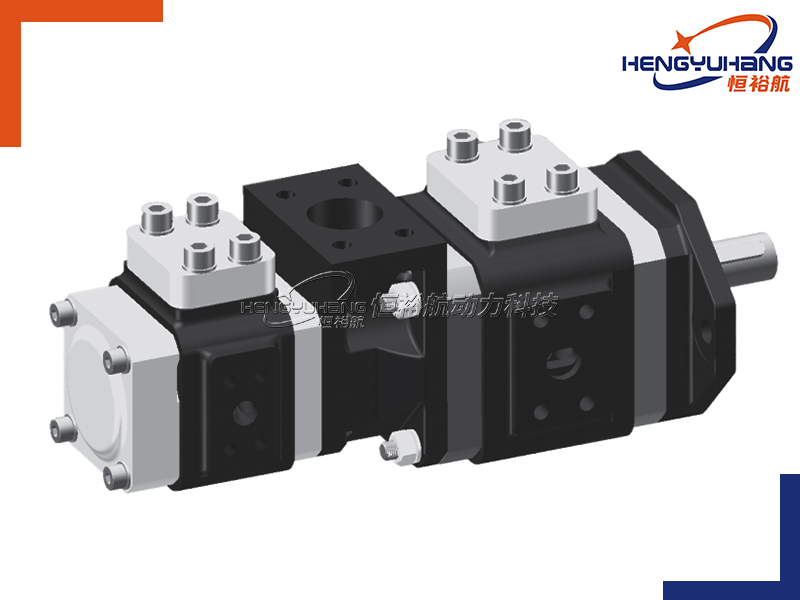

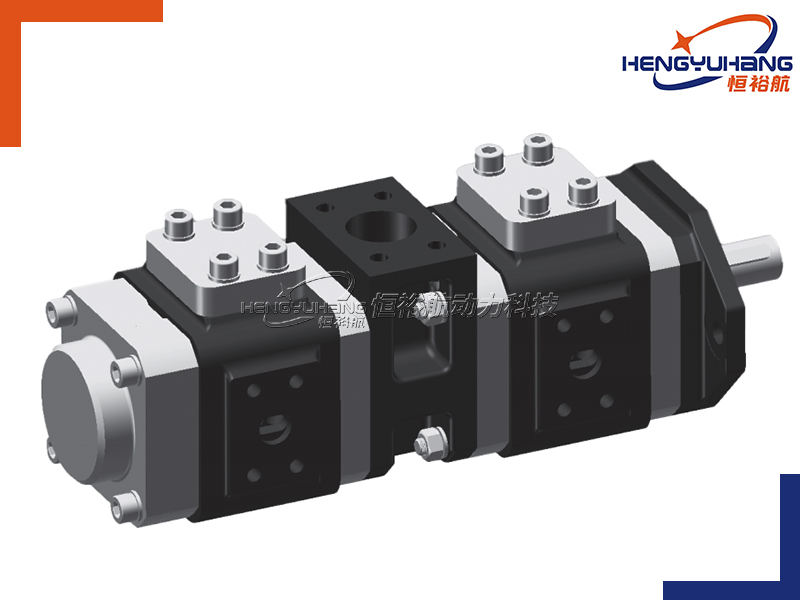

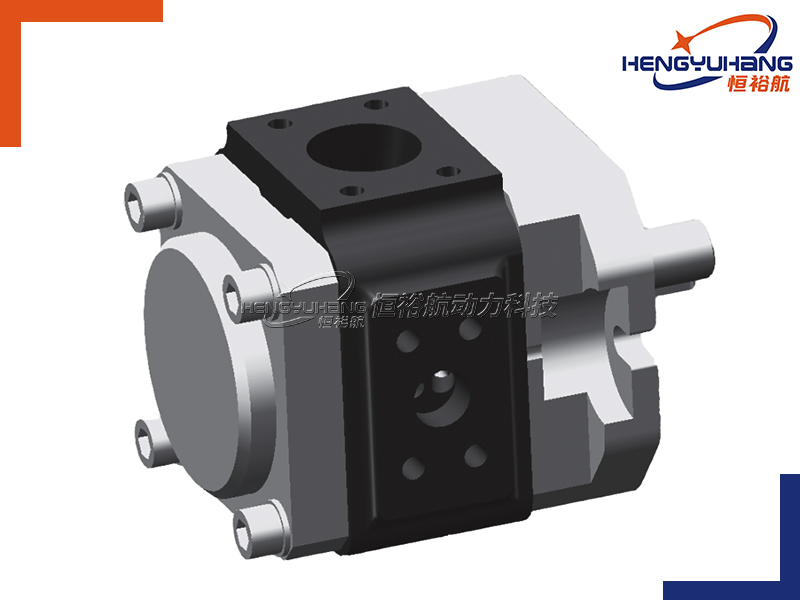

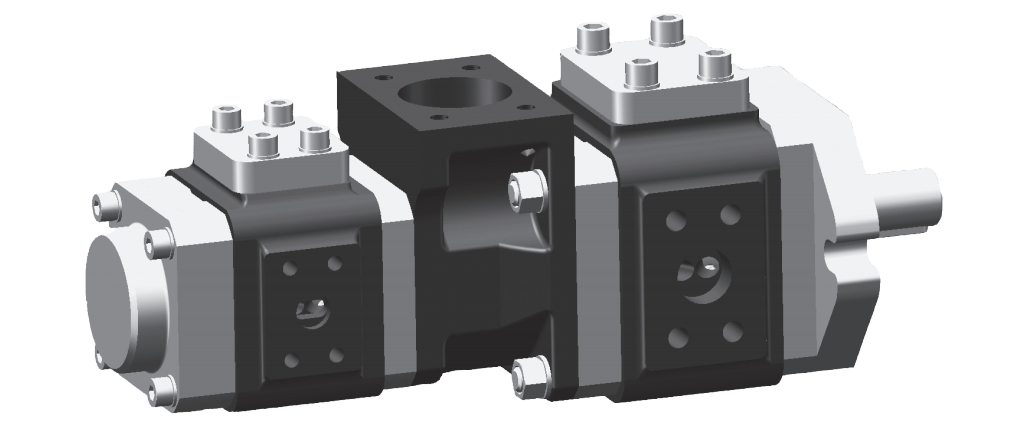

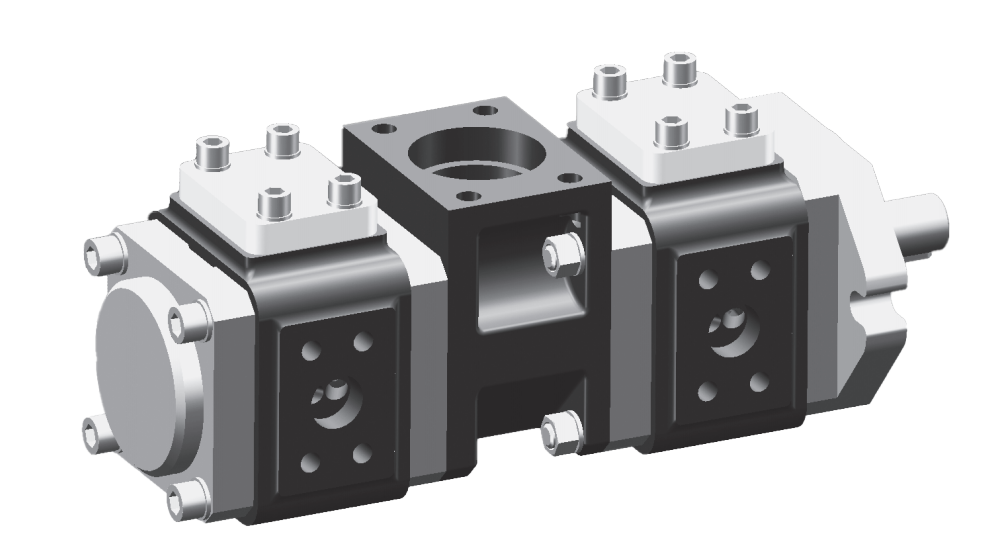

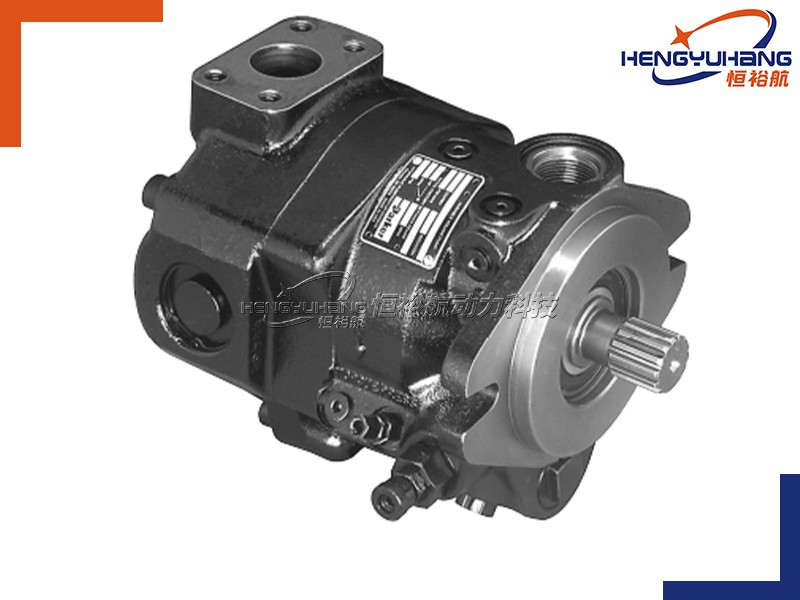

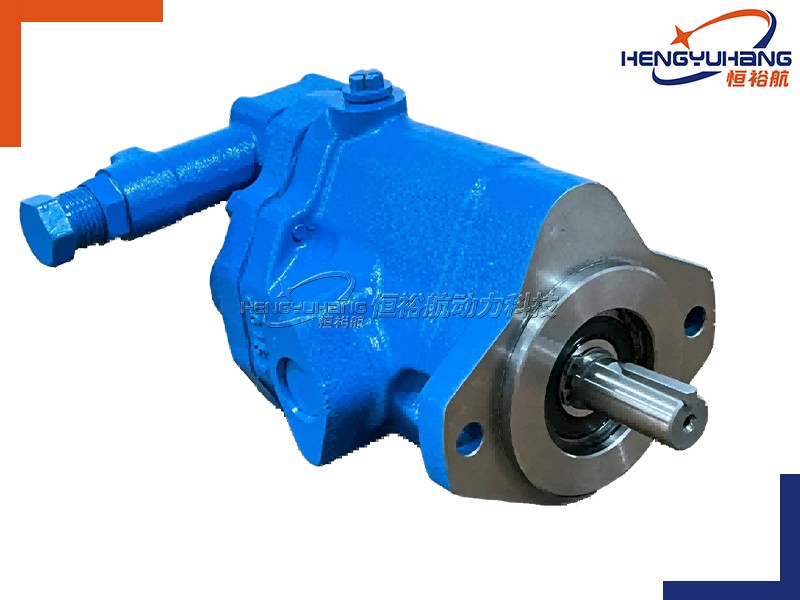

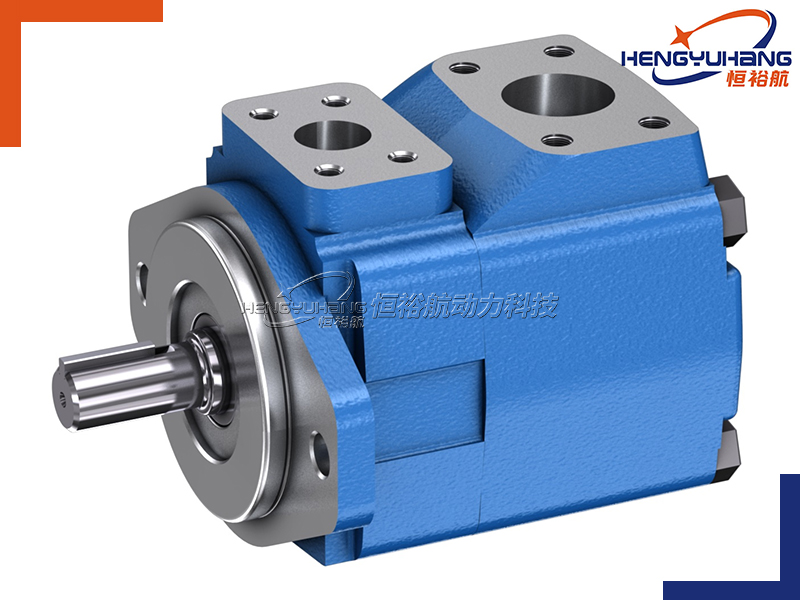

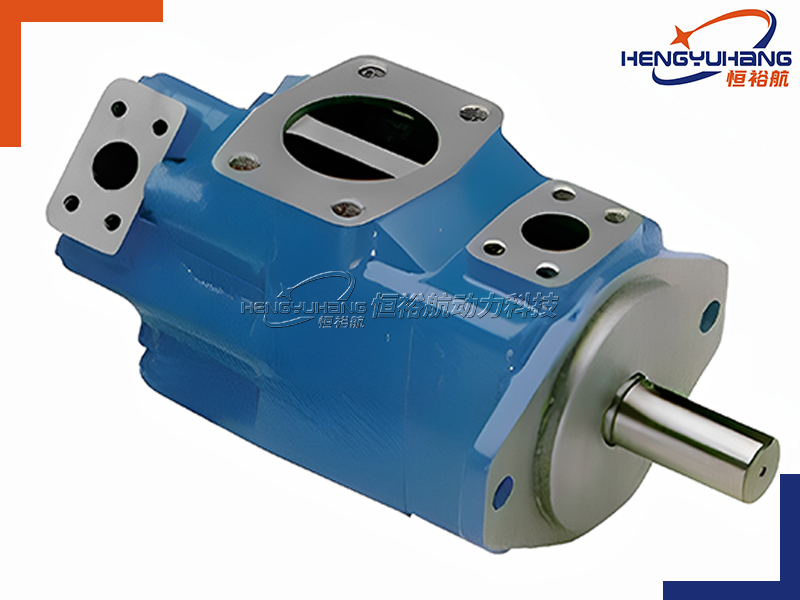

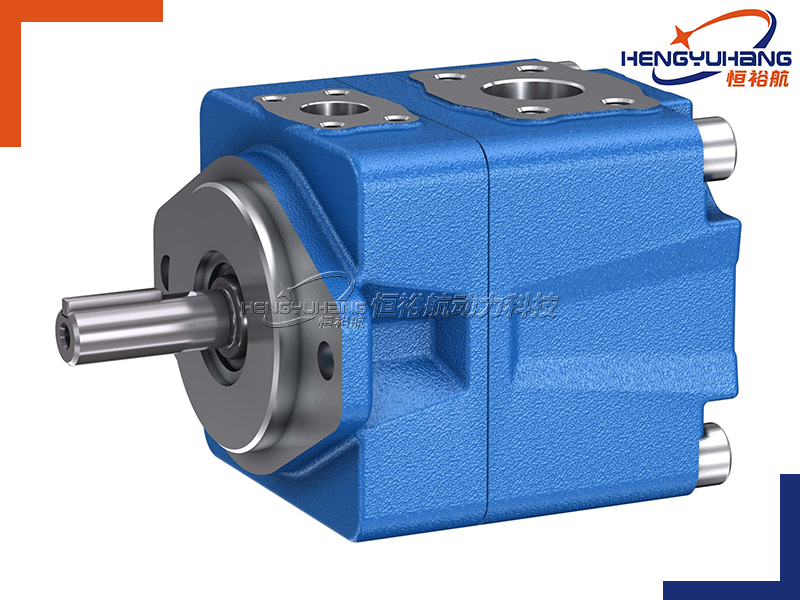

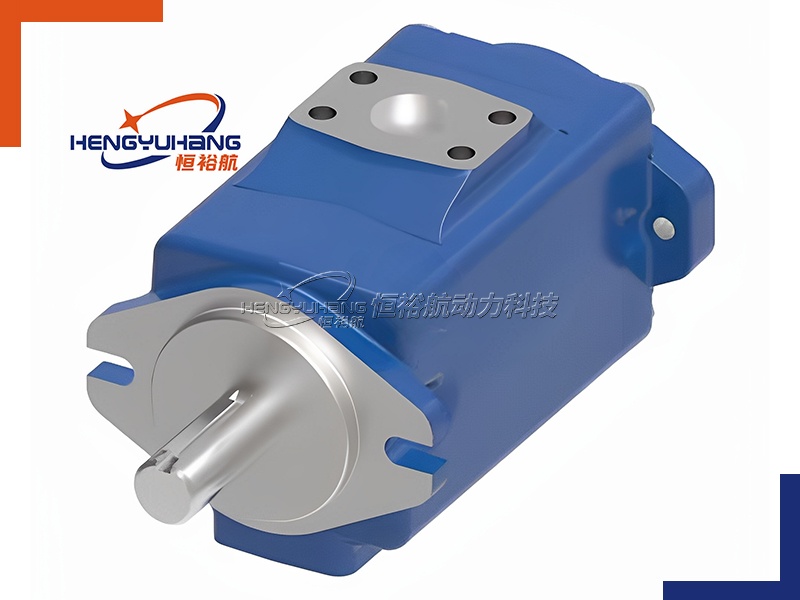

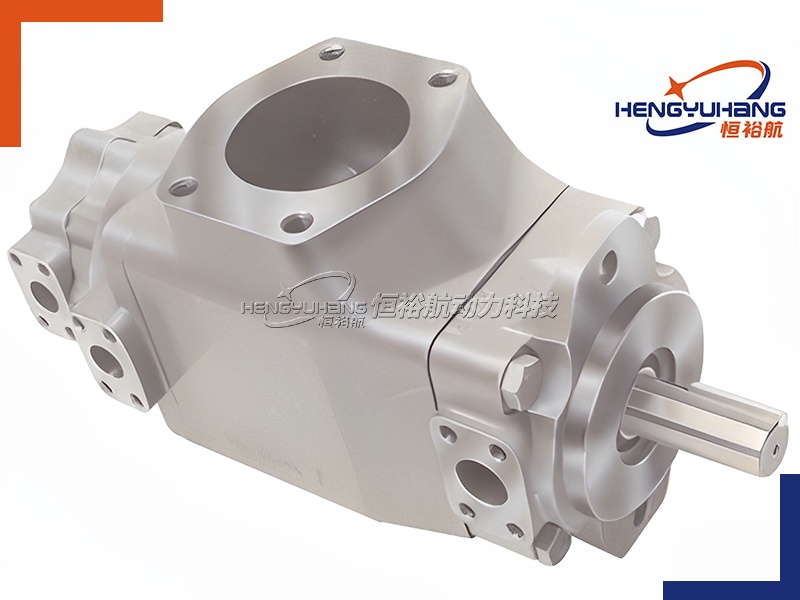

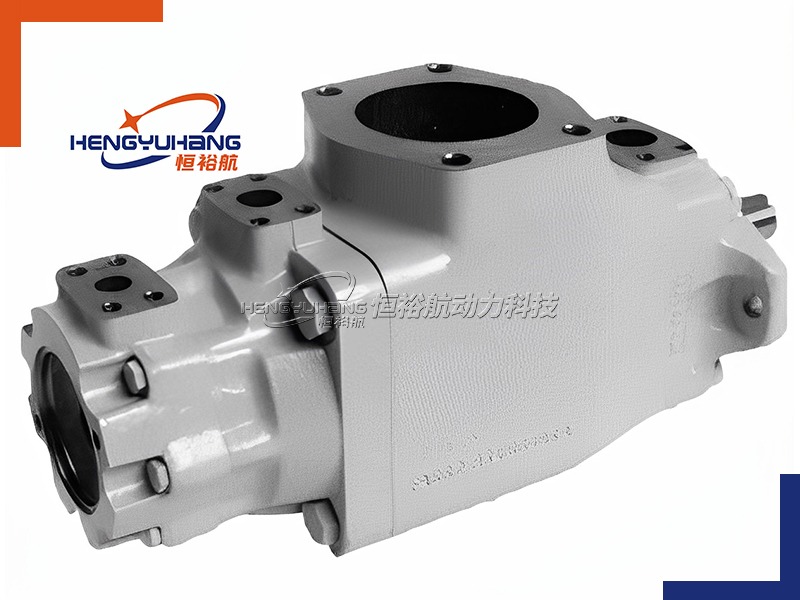

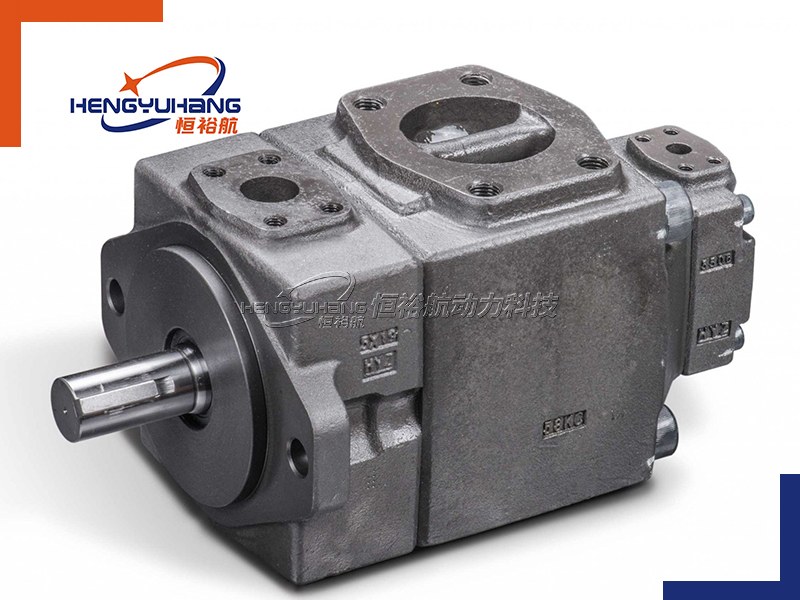

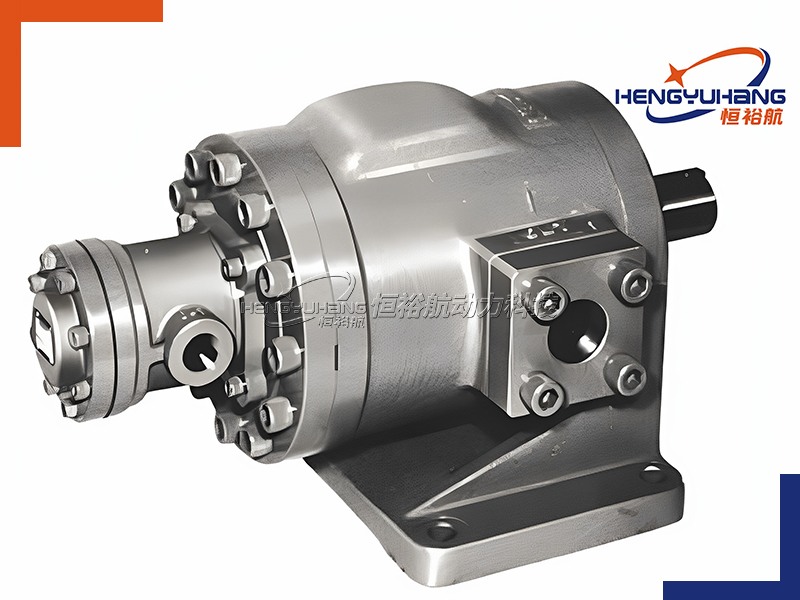

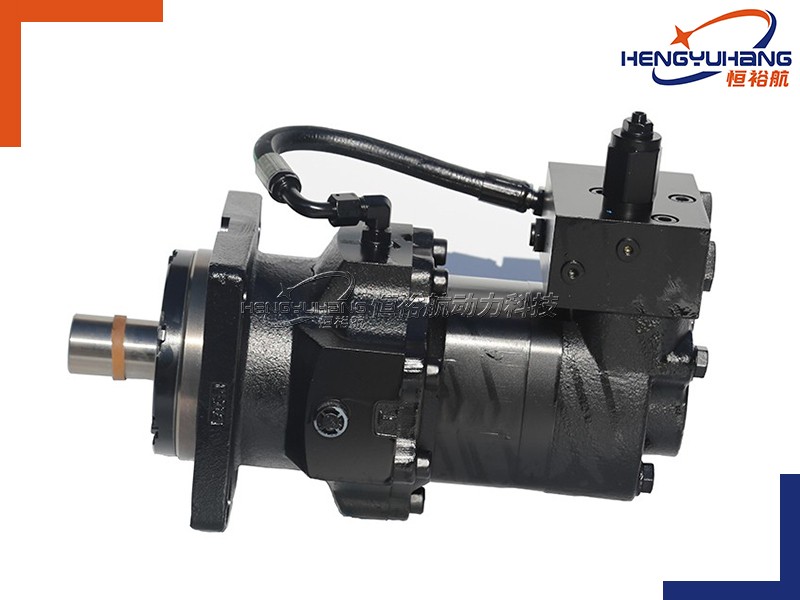

The application of new ductile iron profiles in ultra-high pressure bidirectional reduction motors, with their high strength, high density and low defect characteristics, has significantly enhanced the performance and reliability of the motors

The ultra-high pressure bidirectional reduction motor made of new ductile iron profiles has outstanding comprehensive performance. Its tensile strength is as high as 600MPa, approaching the level of alloy steel, and its elongation is only 3%. This characteristic enables it to exhibit extremely high dimensional stability and anti-deformation ability under ultra-high pressure working conditions. This material achieves an extremely high density through advanced casting techniques, completely eliminating the common porosity and sand holes in traditional casting, thereby significantly enhancing the pressure resistance and fatigue life of the components.