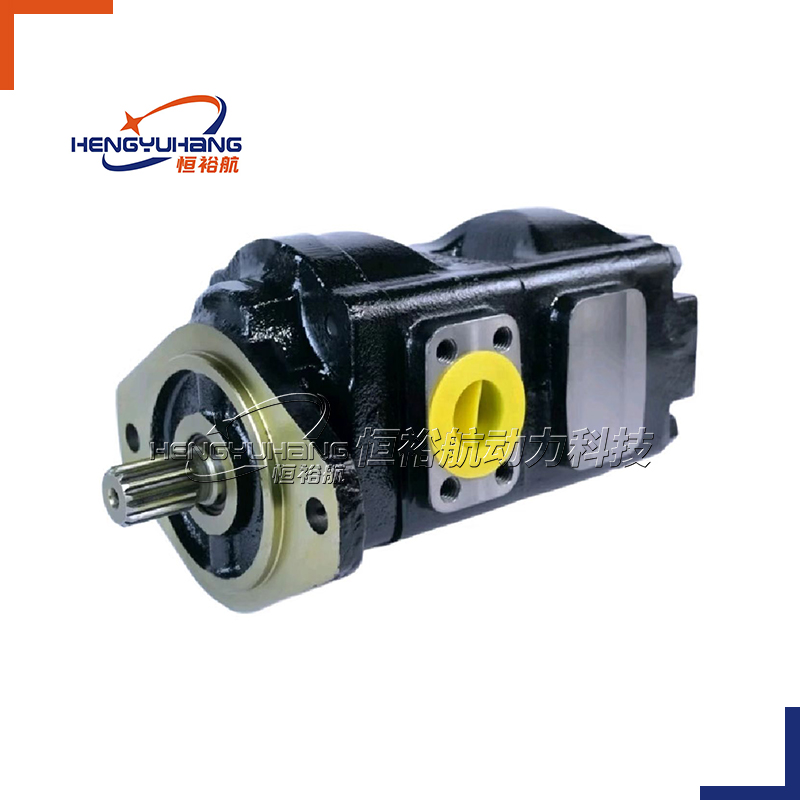

John Deere 310SK / 315SK / 325J / 325K / 325SK / 310SJ / 310G / 315SJ Gear Pump is a heavy-duty hydraulic gear pump. It features high efficiency, strong durability, and long service life, helping to solve problems such as insufficient hydraulic power and system instability. It is widely used in construction machinery, building operations, agricultural work, and material handling industries.

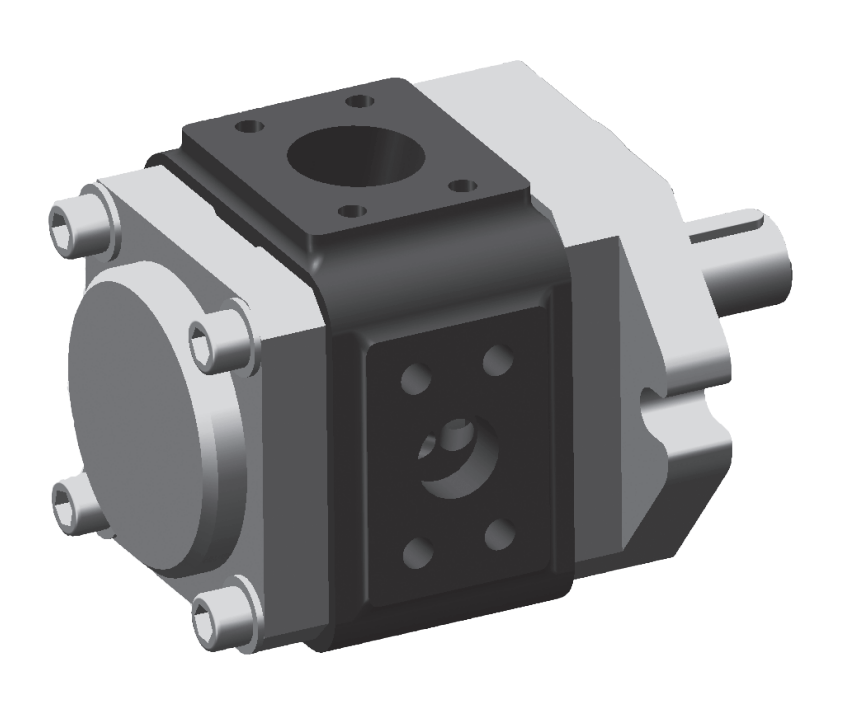

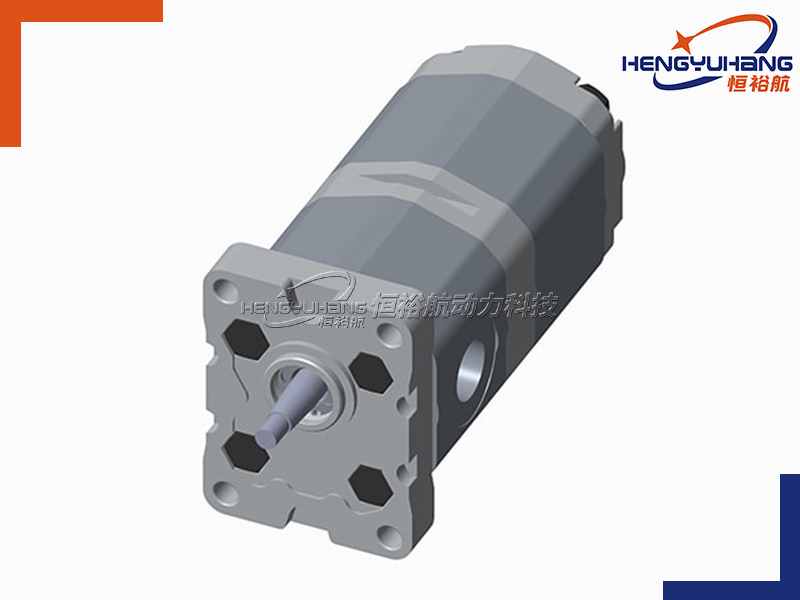

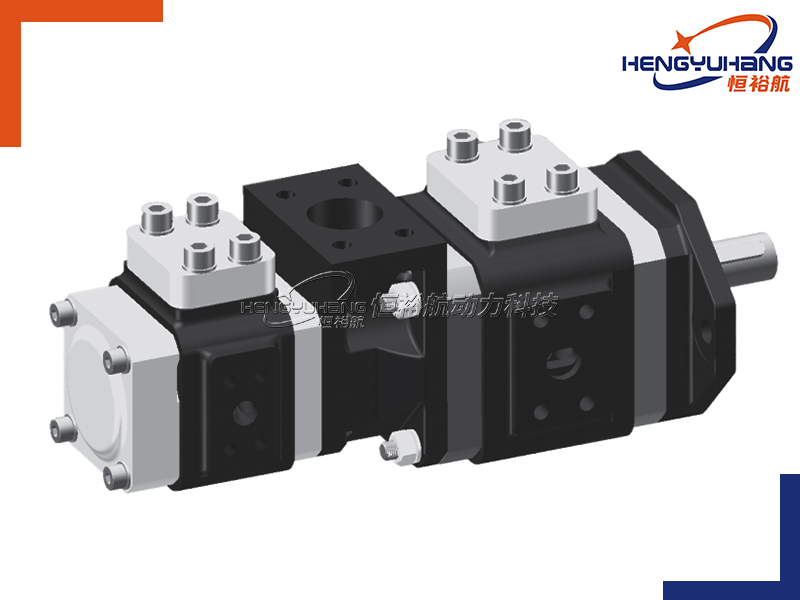

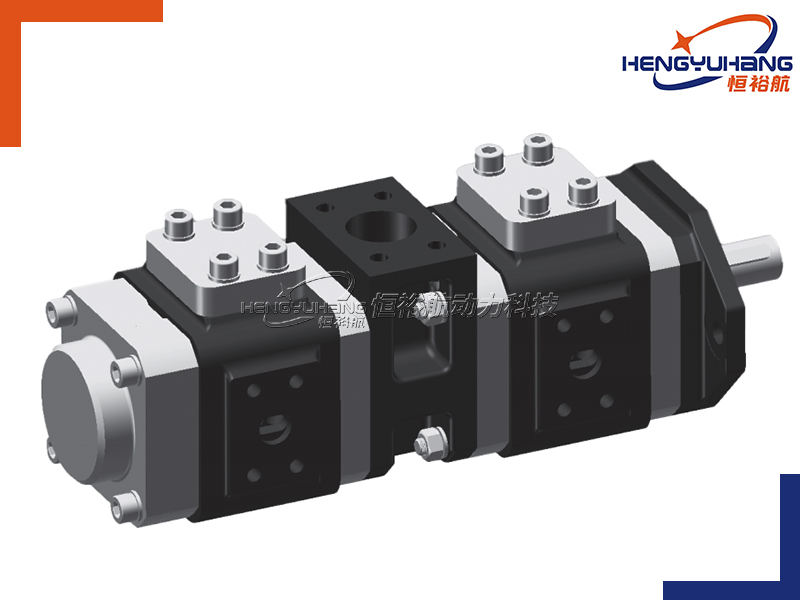

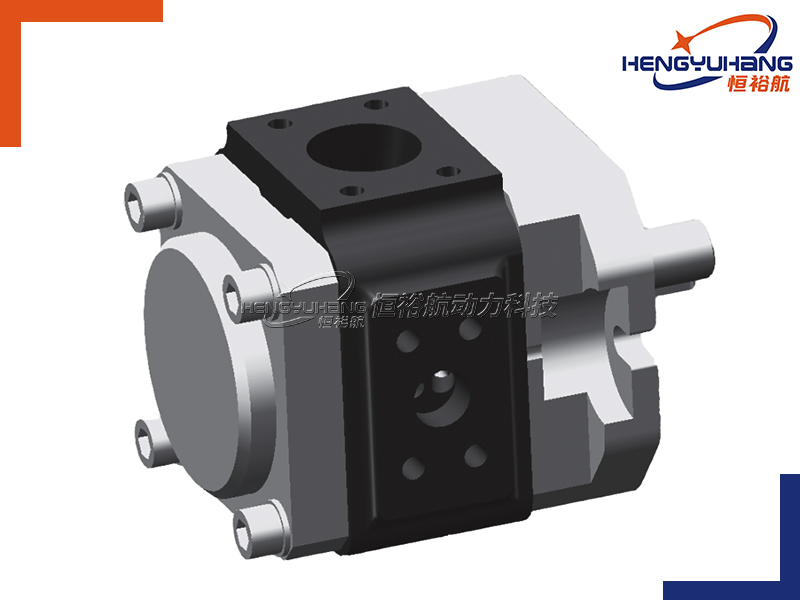

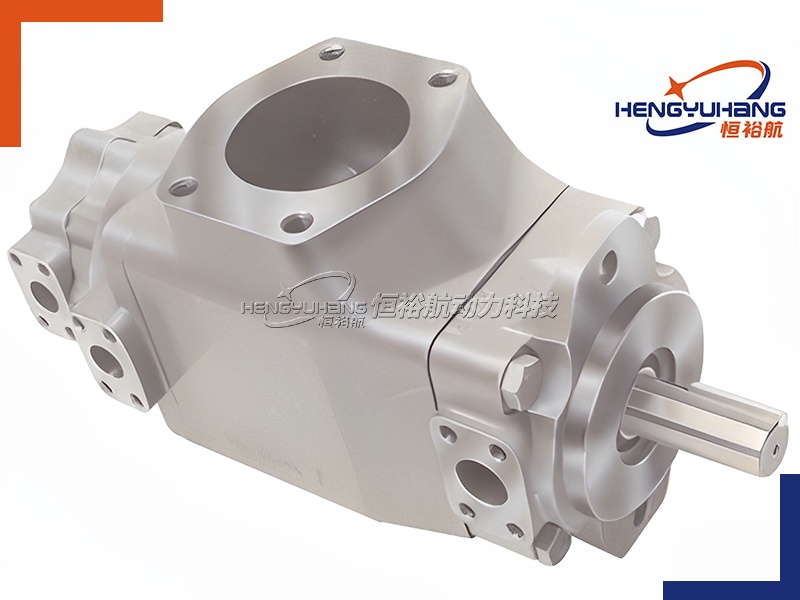

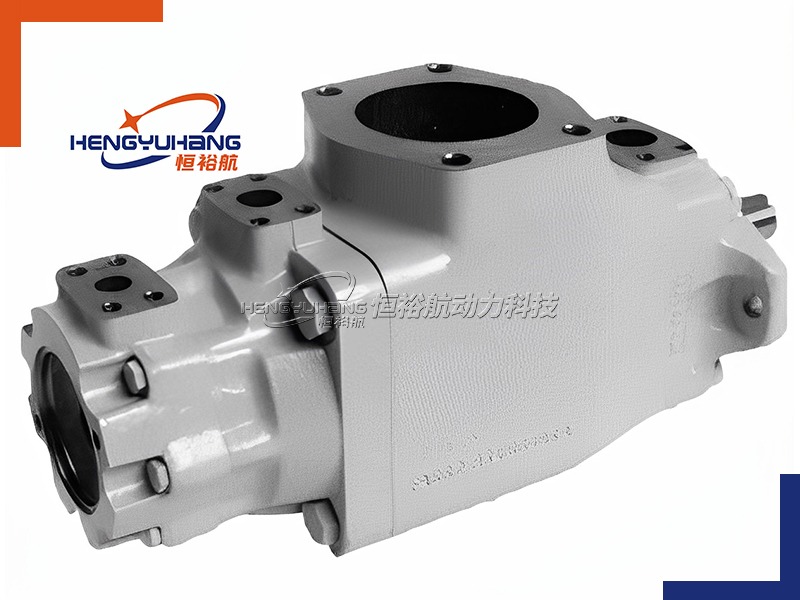

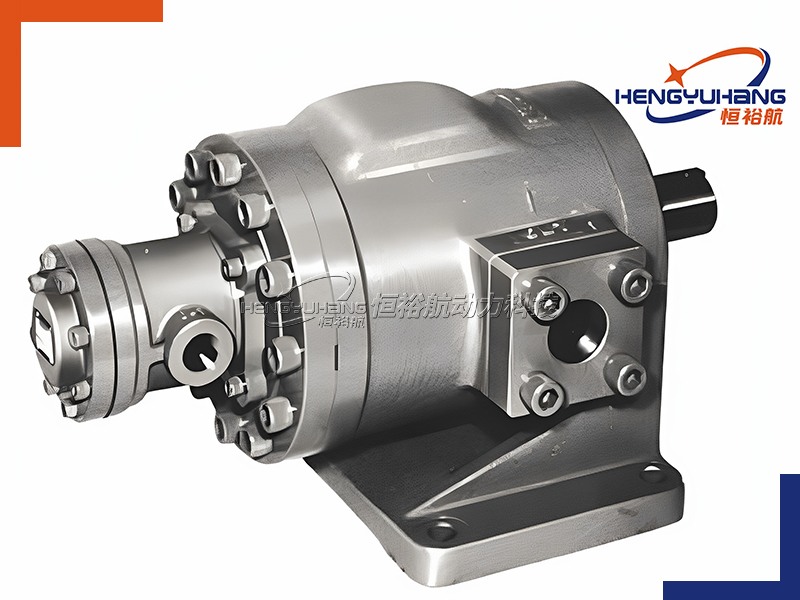

Internal meshing Gear Pump, Group 5PHF(80~160cm³/rev.)

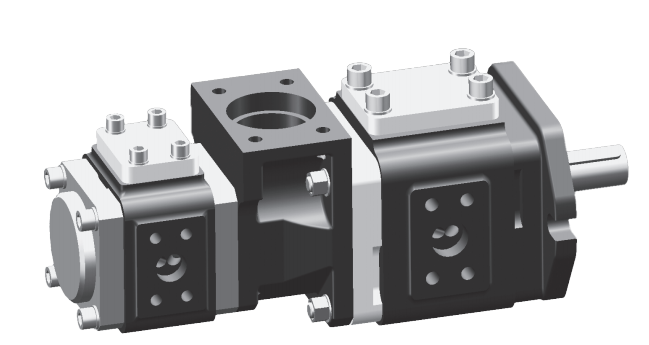

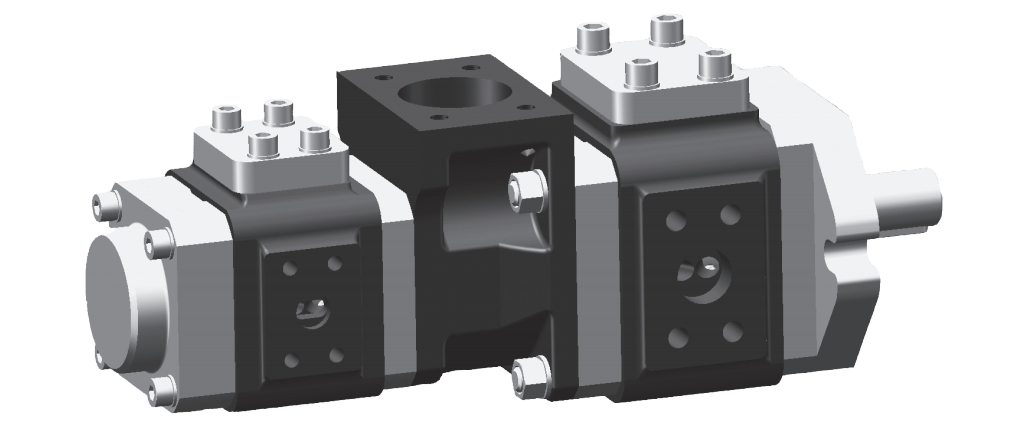

Internal meshing Gear Pump, Group 5PHF+4PHF(80~160cm³/rev.)

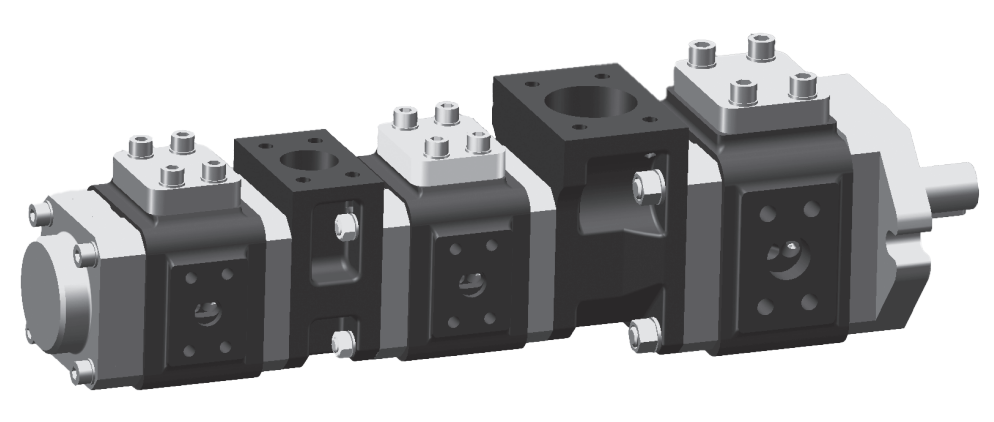

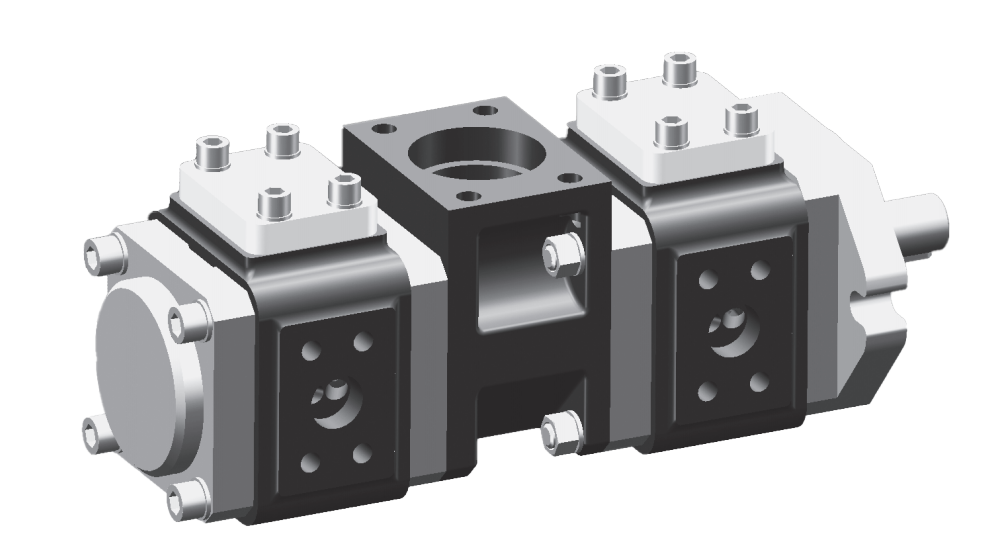

Internal meshing Gear Pump, Group 5PHF+4PHF+3PHF(80~160cm³/rev.)

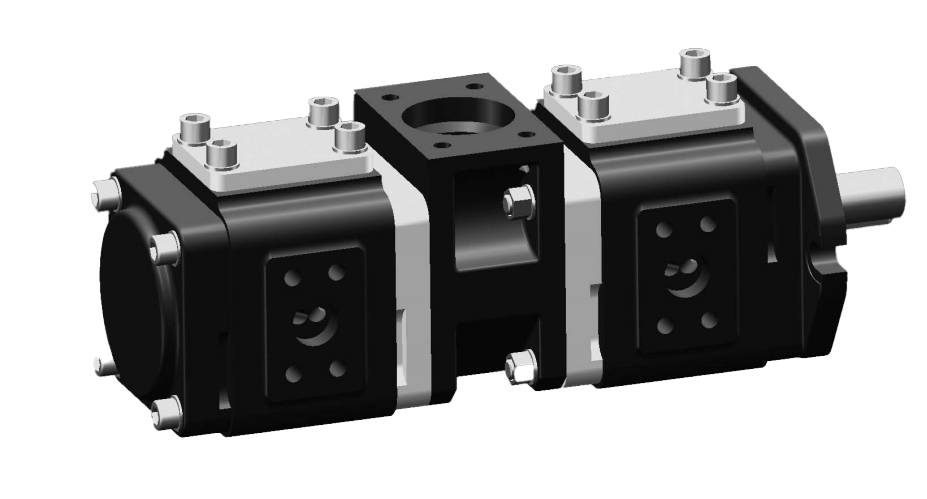

Internal meshing Gear Pump, Group 5PHF+5PHF(80~160cm³/rev.)

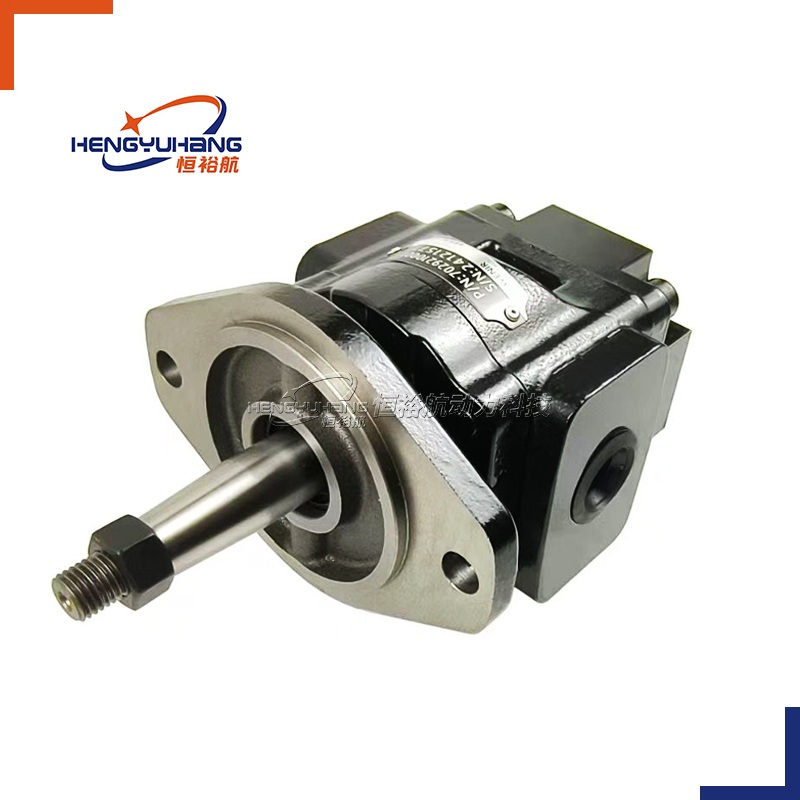

Mini External Gear Pump, Group 0PUF (0.19~2cm³/rev.)

Mini External Gear Pump, Group 1PUF (0.8~8cm³/rev.)

External Gear Pump, Group 1PDF (1.4~13.8cm³/rev.)

External Gear Pump, Group 1.5PDF (2~12cm³/rev.)

External Gear Pump, Group 2PDF (3~30cm³/rev.)

External Gear Pump, Group 2.5PDF (23~40cm³/rev.)

External Gear Pump, Group 3PDF (20~71cm³/rev.)

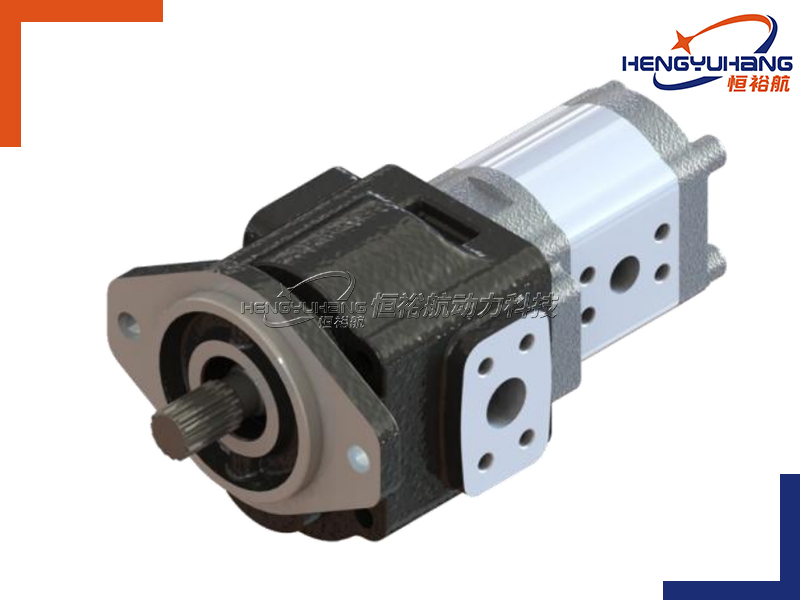

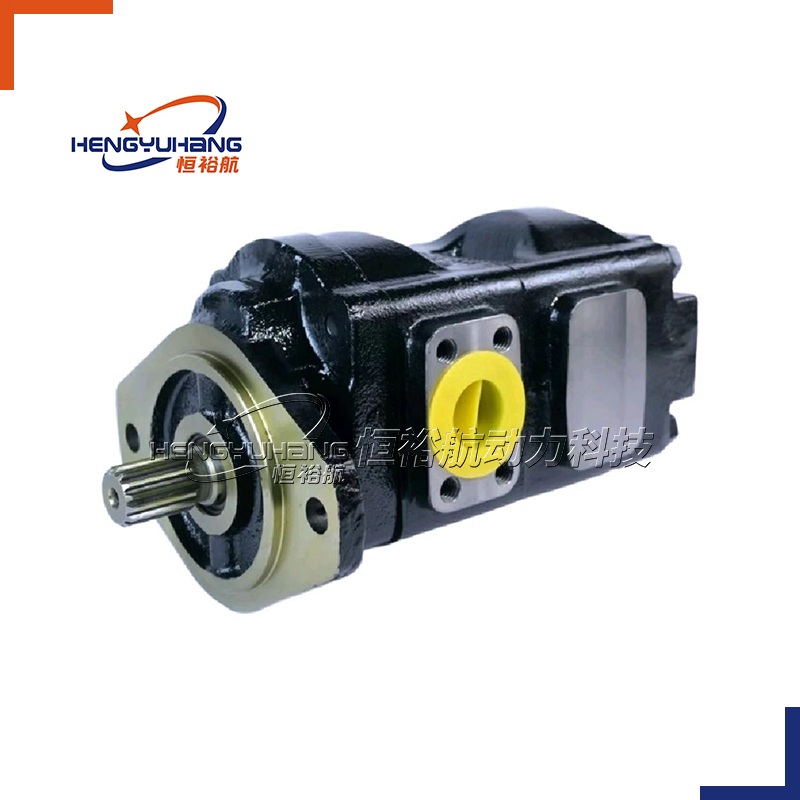

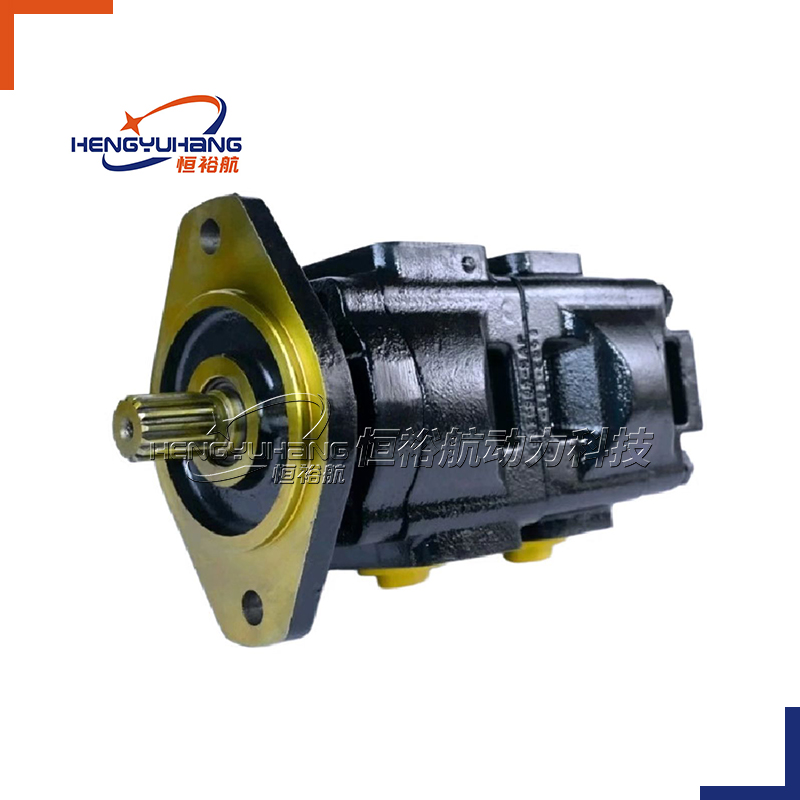

Tandem Gear Pump, Group 1PUF + Group 1PUF (0.8~13.8cm³/rev.)

Tandem Gear Pump, Group 1PDF + Group 1PDF (1.4~13.8cm³/rev.)

Tandem Gear Pump, Group 2PDF + Group 1PUF (0.8~30cm³/rev.)

Tandem Gear Pump, Group 2PDF + Group 2PDF (0.8~30cm³/rev.)

Tandem Gear Pump, Group 2.5PDF + Group 2.5PDF (10~45cm³/rev.)

Tandem Gear Pump, Group 3PDF + Group 1PUF(0.8~71cm³/rev.)

Tandem Gear Pump, Group 3PDF + Group 2PDF (3~71cm³/rev.)

Tandem Gear Pump, Group 3PDF + Group 3PDF (3~71cm³/rev.)

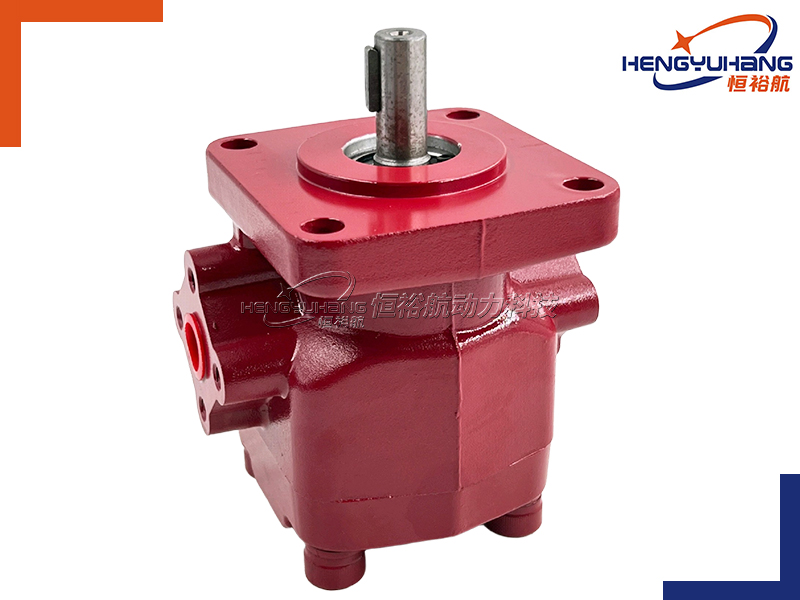

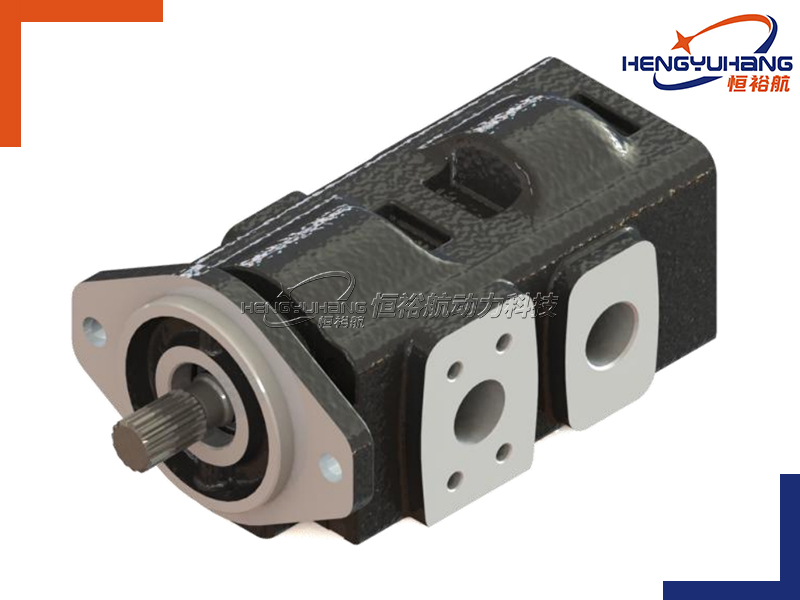

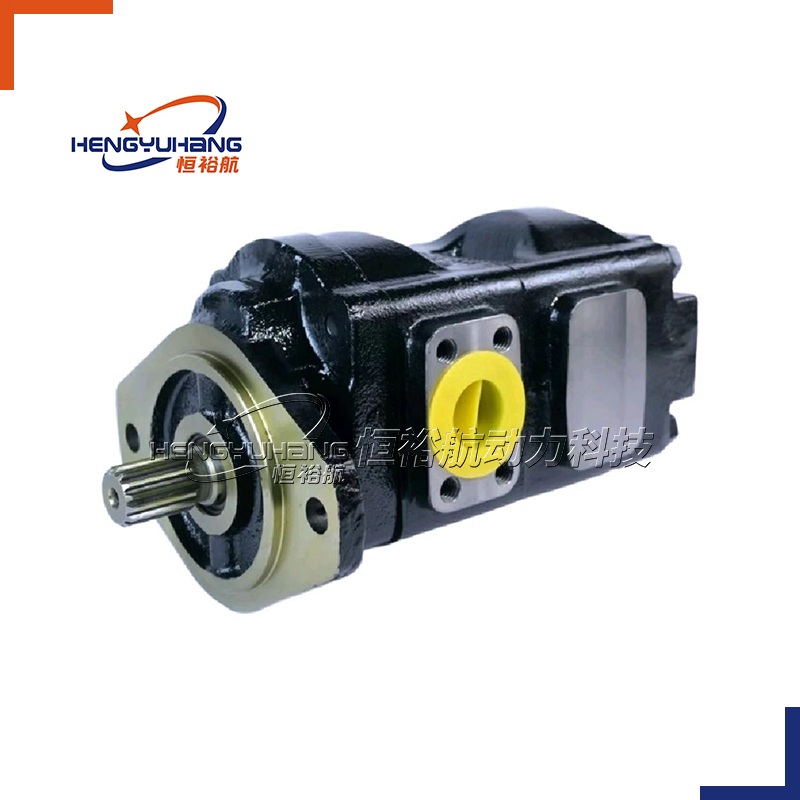

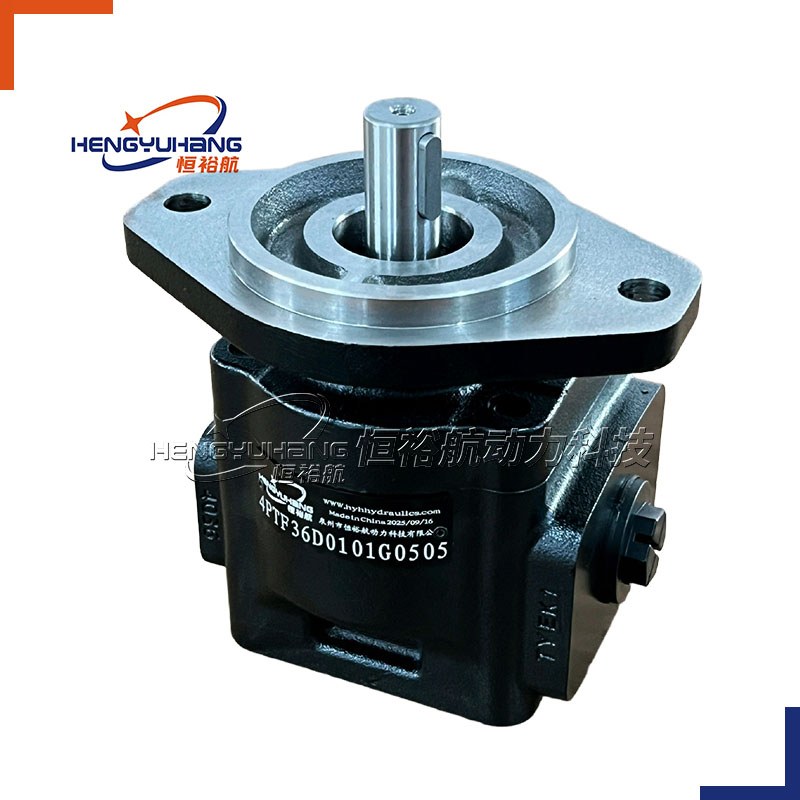

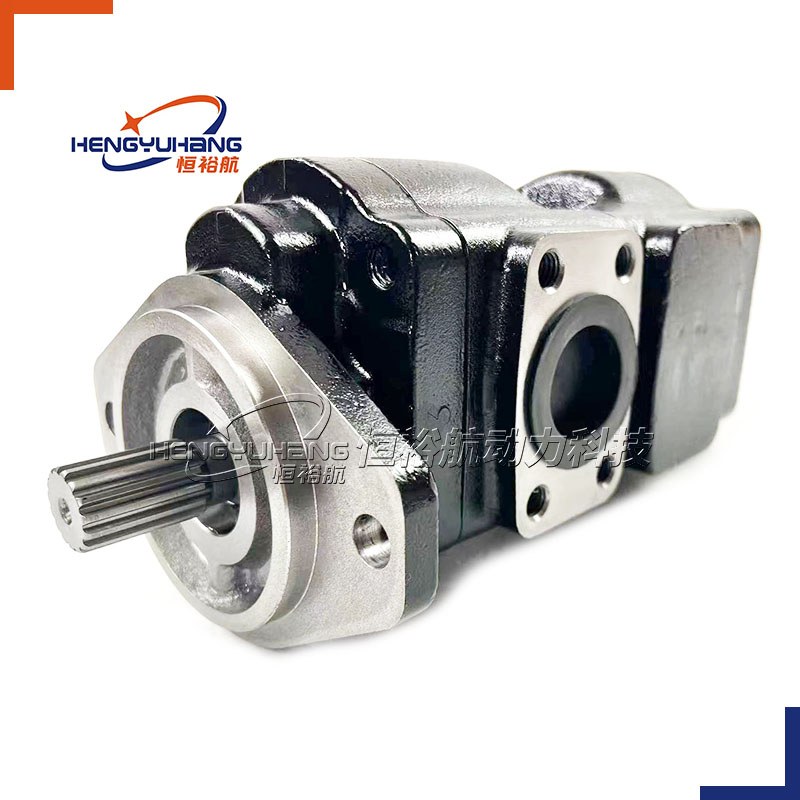

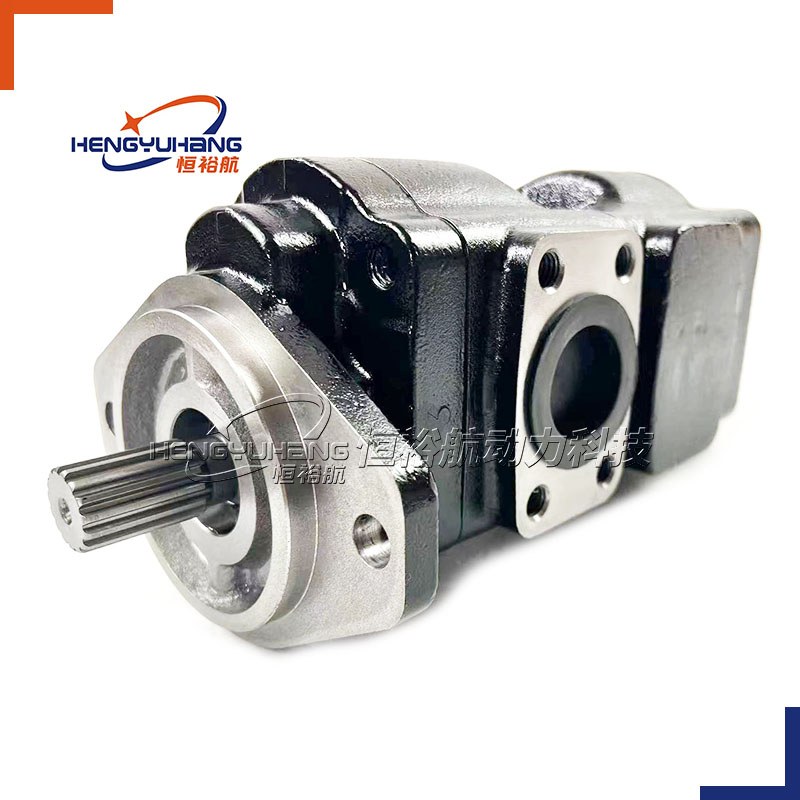

Cast iron External Gear Pump, Group 2PTF(3~30cm³/rev.)

Cast iron External Gear Pump, Group 3PTF(20~71cm³/rev.)

Cast iron External Gear Pump, Group 4PTF(8~92cm³/rev.)

Cast iron External Gear Pump, Group 5PTF(15~125cm³/rev.)

Cast iron External Gear Pump,Group 6PTF(20~250cm³/rev.)

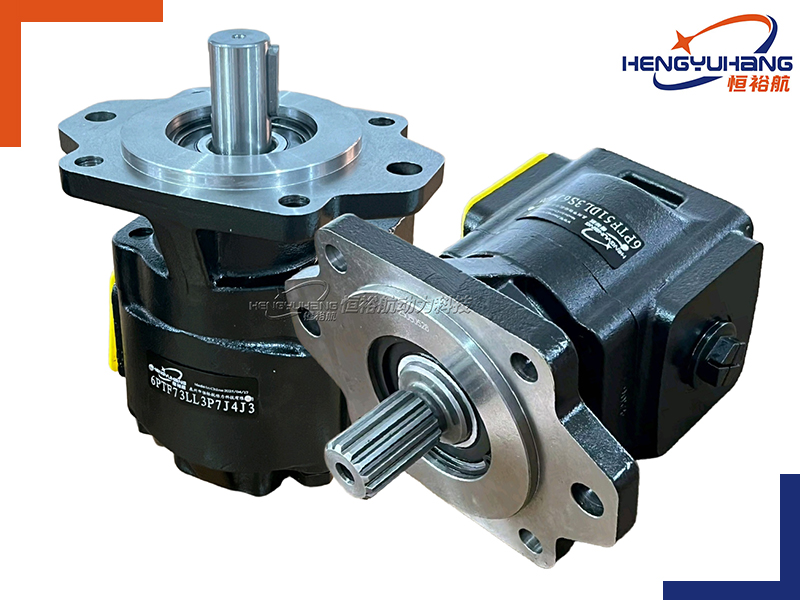

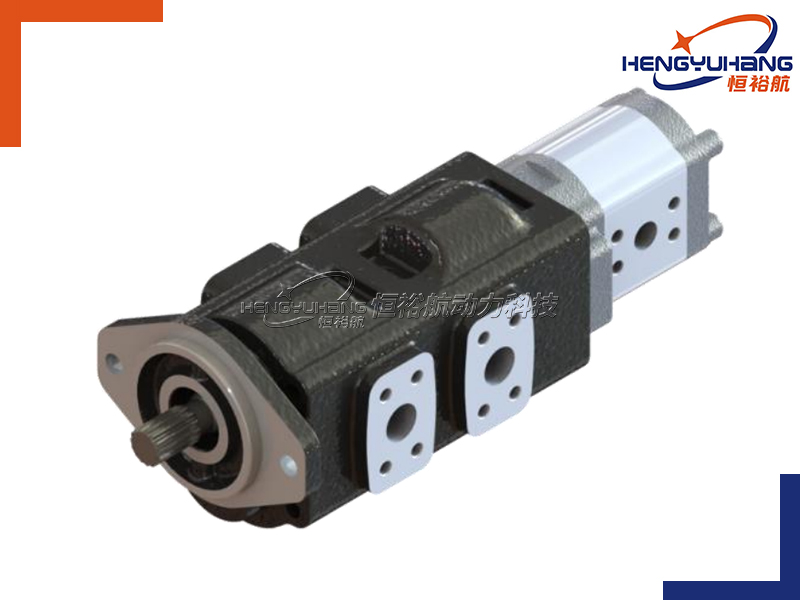

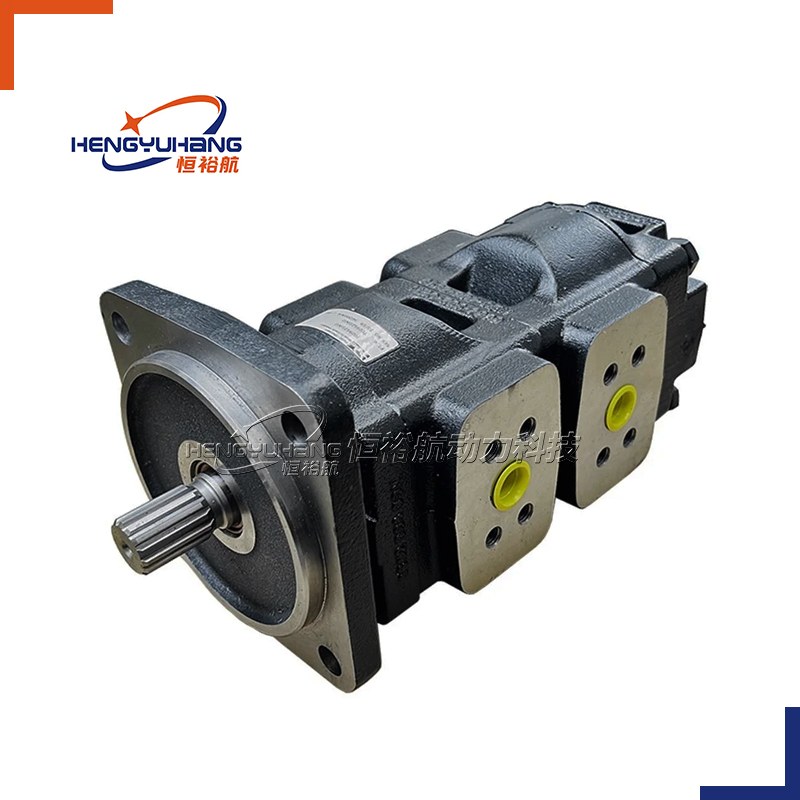

Cast iron External Gear Pump, Group 2PTF multi-pump combination(3~30cm³/rev.)

Cast iron External Gear Pump, Group 3PTF multi-pump combination(20~71cm³/rev.)

Cast iron External Gear Pump, Group 4PTF multi-pump combination (8~92cm³/rev.)

Cast iron External Gear Pump, Group 5PTF multi-pump combination (15~125cm³/rev.)

Cast iron External Gear Pump,Group 6PTF multi-pump combination(20~250cm³/rev.)

Internal meshing Gear Pump, Group 2PHF(4.2~25.2cm³/rev.)

External Gear Pump, Group 3PDF (20~71cm³/rev.)

External Gear Pump, Group 2PDF (4~30cm³/rev.)

Mini External Gear Pump, Group 0PUF (0.19~2cm³/rev.)

External Gear Pump, Group 2PDF (3~30cm³/rev.)

Internal meshing Gear Pump, Group 2PHF+2PHF(4.2~25.2cm³/rev.)

Internal meshing Gear Pump, Group 3PHF(24.8~63.1cm³/rev.)

Internal meshing Gear Pump, Group 3PHF+2PHF(24.8~63.1cm³/rev.)

Internal meshing Gear Pump, Group 3PHF+3PHF(24.8~63.1cm³/rev.)

Internal meshing Gear Pump, Group 4PHF(65.3~100.5cm³/rev.)

Internal meshing Gear Pump, Group 4PHF+2PHF(65.3~100.5cm³/rev.)

Internal meshing Gear Pump, Group 4PHF+3PHF+3PHF(25~100cm³/rev.)

Internal meshing Gear Pump, Group 4PHF+3PHF(65.3~100.5cm³/rev.)

Internal meshing Gear Pump, Group 4PHF+4PHF(65.3~100.5cm³/rev.)

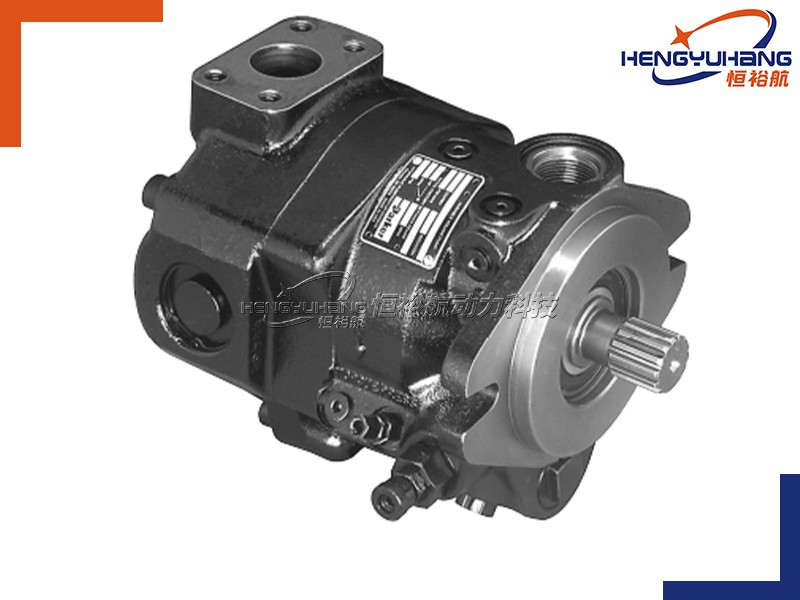

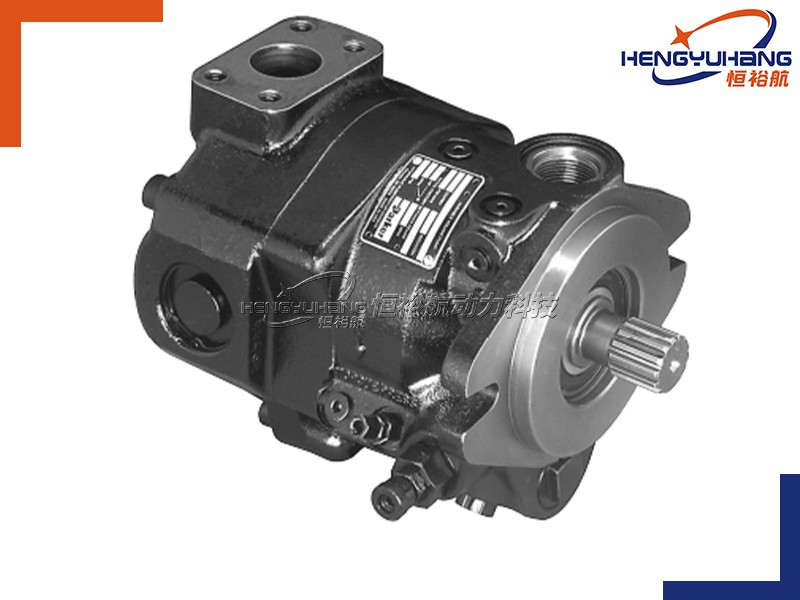

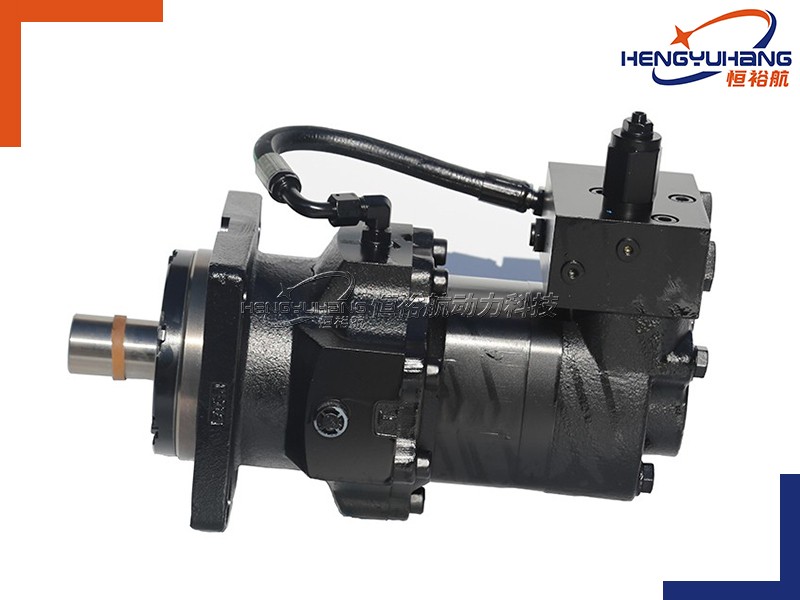

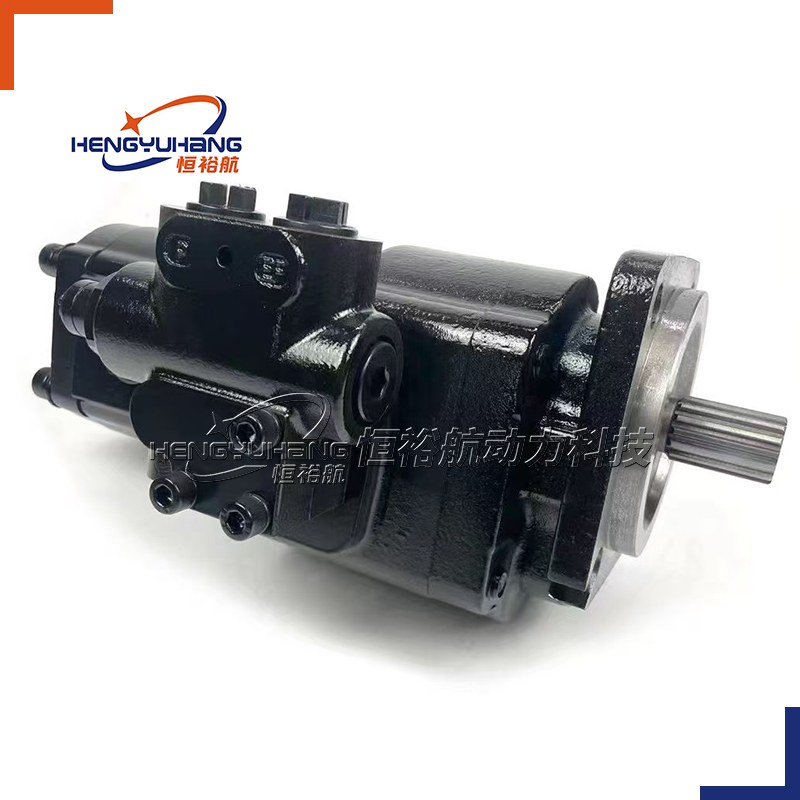

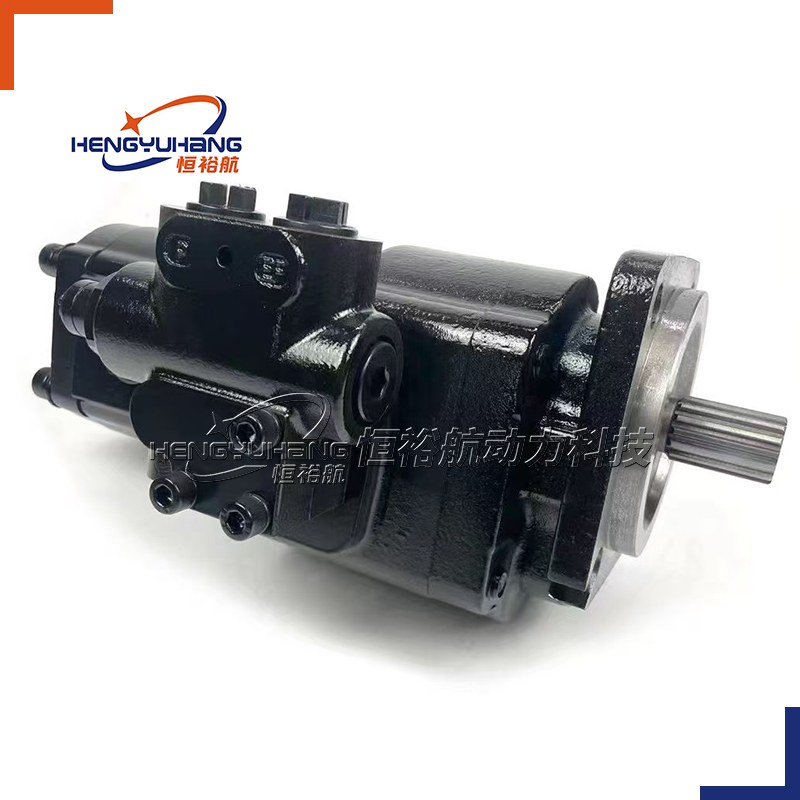

Axial piston variable pump A4VG(28~180cm³/rev.)

Axial piston variable pump A4VHO(450cm³/rev.)

Axial piston variable pump A4VSG(40~1000cm³/rev.)

Axial piston variable pump A4VSO(40~1000cm³/rev.)

Axial piston variable pump A7VO(28~500cm³/rev.)

Axial piston variable pump A8VO(55~225cm³/rev.)

Axial piston variable pump A10VNO(28~85cm³/rev.)

Axial piston variable pump A10VO Series 31(18~100cm³/rev.)

Axial piston variable pump A10VO Series 32(45~180cm³/rev.)

Axial piston variable pump A10VO Series 5X(10~100cm³/rev.)

Axial piston variable pump A10VO Series 60(45cm³/rev.)

Axial piston variable pump A10VSO 10 Series 5X(10cm³/rev.)

Axial piston variable pump A10VSO Series 31(18~100cm³/rev.)

Axial piston variable pump A10VSO Series 32(45~180cm³/rev.)

Axial piston variable pump A11VLO Series 1x(40~260cm³/rev.)

Axial piston variable pump A11VLO Series 1x(40~260cm³/rev.)

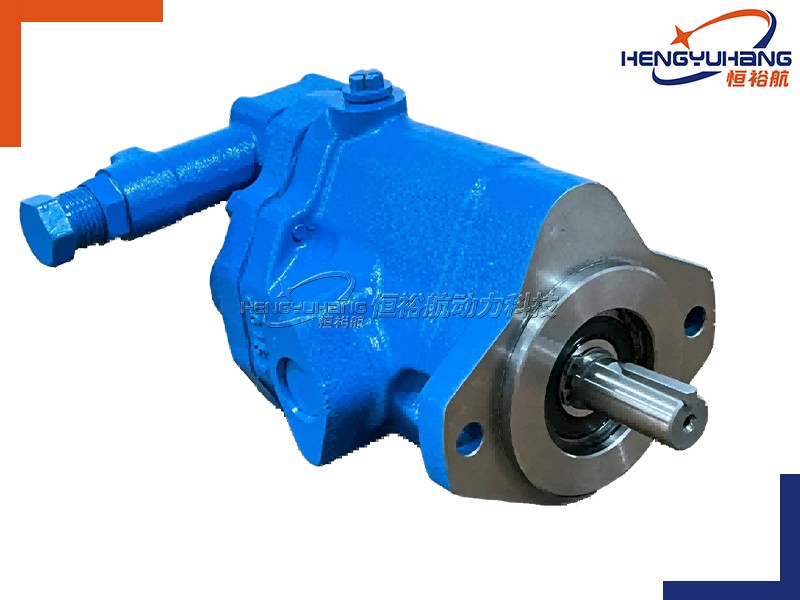

Axial piston variable pump P1(18~140cm³/rev.)

Axial piston variable pump PAVC(33~100cm³/rev.)

Axial piston variable pump PD(18~140cm³/rev.)

Axial piston variable pump PV(16~360cm³/rev.)

Axial piston variable pump PVB(10~200cm³/rev.)

Axial piston variable pump PVE(25~67cm³/rev.)

Axial piston variable pump PVH(57~141cm³/rev.)

Axial piston variable pump PVP(16~48cm³/rev.)

Axial piston variable pump PVQ(10~45cm³/rev.)

Axial piston variable pump PVXS(66~250cm³/rev.)

Axial piston variable pump A2FO 70(45~125cm³/rev.)

Axial piston variable pump A2FO 6X(5~32/160~1000cm³/rev.)

Axial piston variable pump A4FO(22~500cm³/rev.)

Axial piston variable pump A17FO(23~125cm³/rev.)

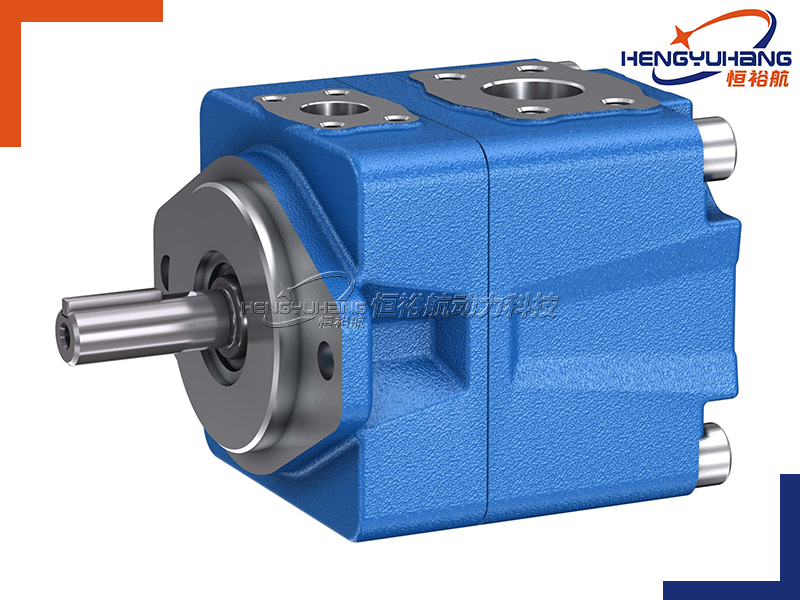

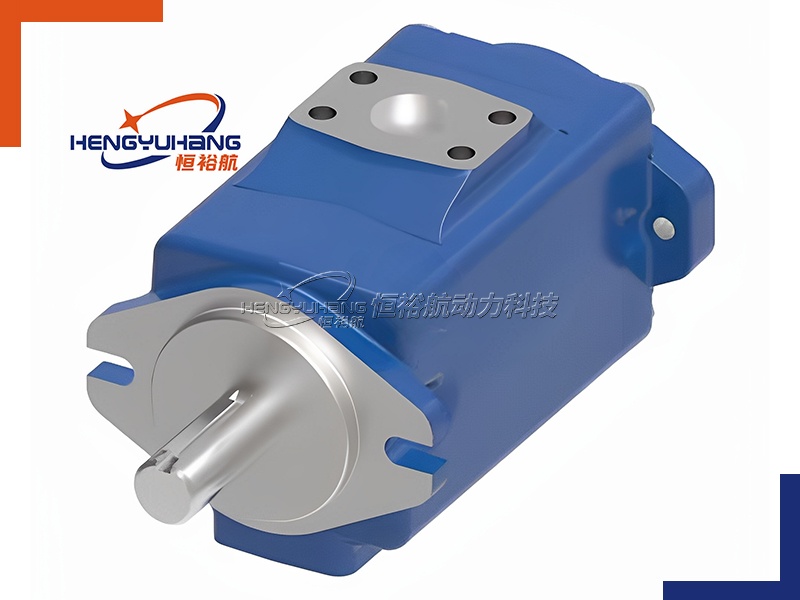

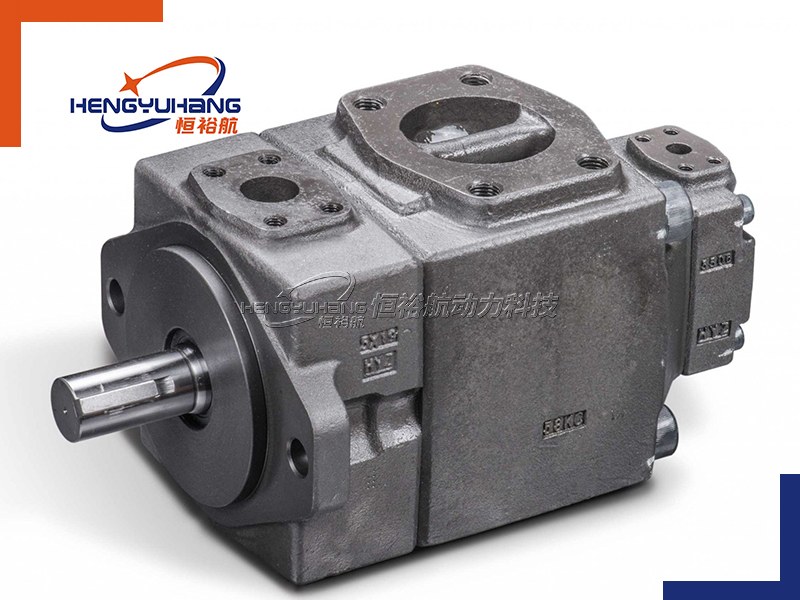

PVV Fixed displacement vane pumps

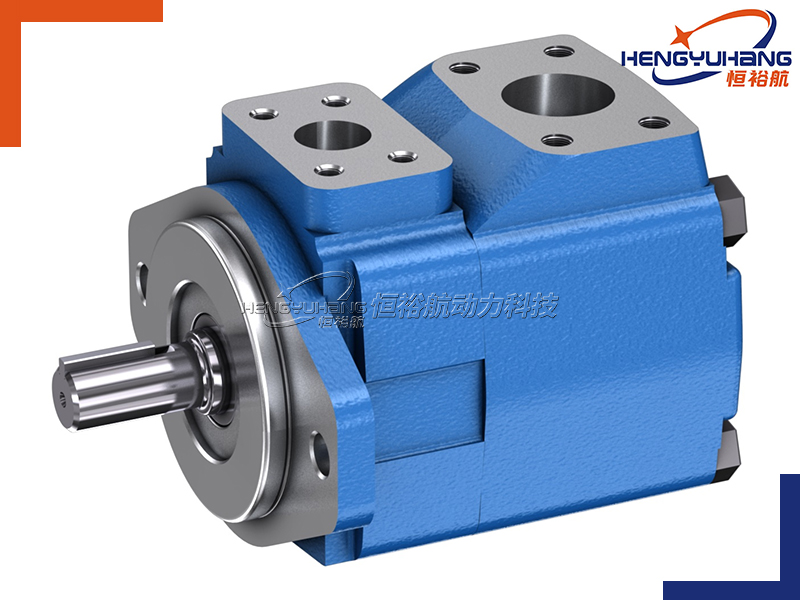

PVV Fixed Displacement Double Vane Pumps

PVH Fixed displacement vane pump

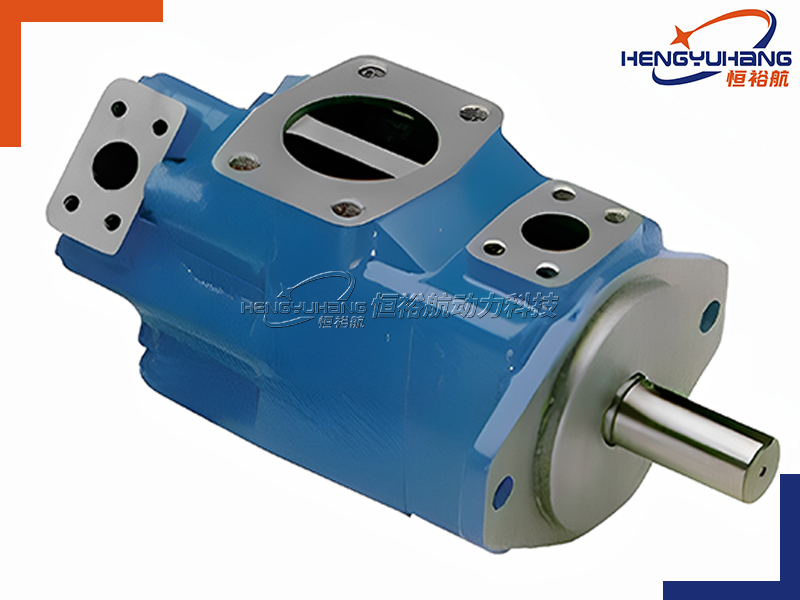

V series vane pump - single

VQ series vane pump - single

V Series Vane pump - Double

VQ Series Vane pump - Double

V Series Single Vane Pump

V Series Double Vane Pump

VMQ Series Single Vane Pump

VMQ Series Double Vane Pump

T7BB T7BBS T67CB T67CBW T6CC T6CCW T67DB T67DBW T6DC T6DCW T6DDS T67EB T6EC T6EE T6EES Series Double Vane Pump

TB Series Single Vane Pump

T7B T7BS T6C T6D T6E Series Single Vane Pump

T67DBB T67DCB T6DCC T67DDBS T6DDCS T67EDB(S) T6EDC(S) Series Three-stage vane pump

T6CR T6DR T6ER Series Tail-driven single Vane Pump

T6EE Series Tail-driven double-Vane pump

T6DCCR T6EDCR Series Tail-driven Threeleafed vane pump

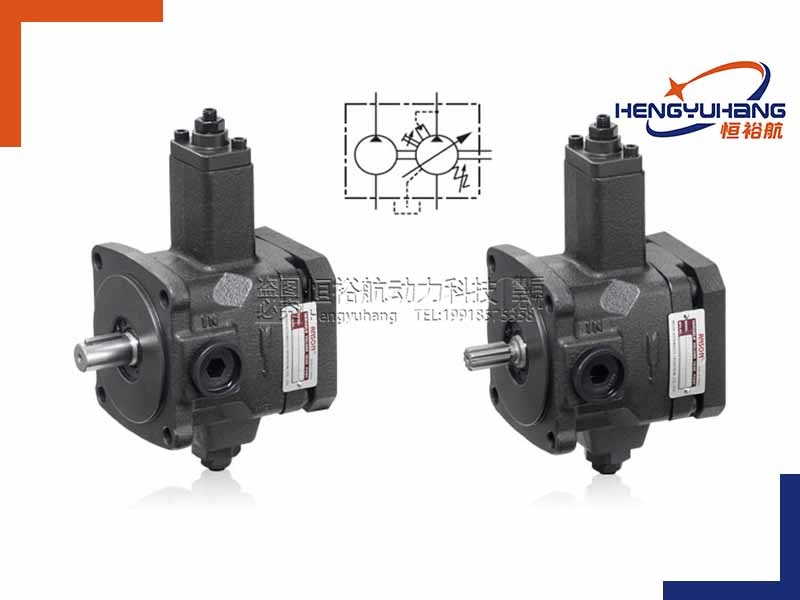

PV2R Series Single vane pump

PV2R Series Double Vane Pump

50T 150T 250F Series Fixed Displacement-Single Vane Pump

5050T 50150T 150150T 50250F 150250F Series Fixed Displacement-Double Vane Pump

SQP SQPS Series single fixed displacement vane pump

SQP SQPS Series double fixed displacement vane pumps

SQP Series triple fixed displacement vane pumps

IVP Series Single Intravane Fixed Displacement Vane Pumps

IVPQ Series Intravane Fixed Displacement Vane Pumps

IVPV Series Intravane Fixed Displacement Vane Pumps

IVP Series Intravane Fixed Displacement Vane Pumps

IVPQ Series Intravane Fixed Displacement Double Vane Pumps

IVPV Series Intravane Fixed Displacement Double Vane Pumps

VP*F Series Variable Displacement Vane Pumps

PVF Series Variable Displacement Vane Pumps

VD Series Variable Displacement Vane Pumps

TPF Series Variable Displacement Vane Pumps

VP*F Series Variable Displacement Vane Pumps

PVDF Series Variable Displacement Vane Pumps

SVD Series Variable Displacement Vane Pumps

PV7-1X Adjustable vane pump, pilot-operated

PV7-1X PV7-2X Adjustable vane pump, direct operated

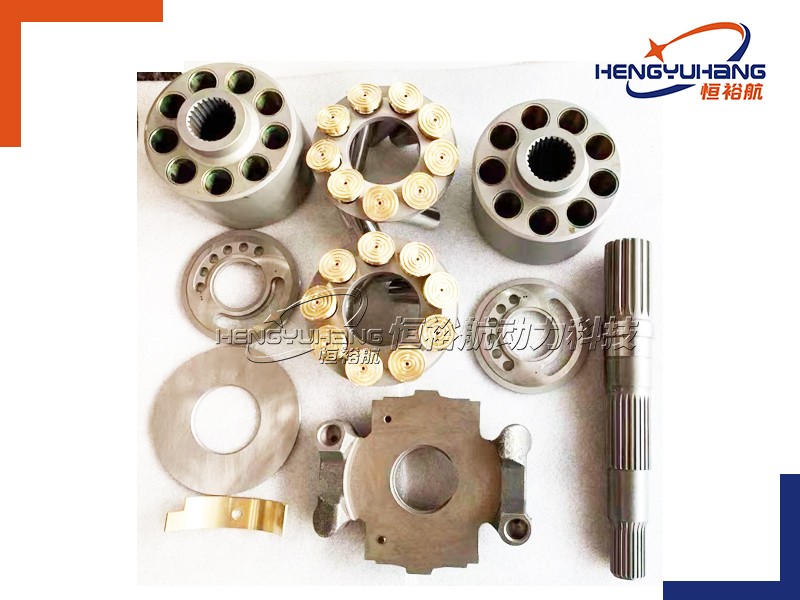

A11VO Hydraulic Rexroth Replacement spare Parts

A11VG Hydraulic Rexroth Replacement spare Parts

A4VG Hydraulic Rexroth Replacement spare Parts

A4VSO Hydraulic Rexroth Replacement spare Parts

A4V Hydraulic Rexroth Replacement spare Parts

A4VTG Hydraulic Rexroth Replacement spare Parts

A10VSO Hydraulic Rexroth Replacement spare Parts

A10VO-52/53 Hydraulic Rexroth Replacement spare Parts

A10VO-31Hydraulic Rexroth Replacement spare Parts

A15VSO Hydraulic Rexroth Replacement spare Parts

A20VO A20VLO Hydraulic Rexroth Replacement spare Parts

A28VO130 Hydraulic Rexroth Replacement spare Parts

A22VG45 Hydraulic Rexroth Replacement spare Parts

A2F Hydraulic Rexroth Replacement spare Parts

A2FO Hydraulic Rexroth Replacement spare Parts

A2FM Hydraulic Rexroth Replacement spare Parts

A2FE Hydraulic Rexroth Replacement spare Parts

A2VK Hydraulic Rexroth Replacement spare Parts

A10VT Hydraulic Rexroth Replacement spare Parts

A10VD Hydraulic Uchida Replacement spare Parts

A10FM A10FE Hydraulic Uchida Replacement spare Parts

A7V Hydraulic Rexroth Replacement spare Parts

A8V Hydraulic Rexroth Replacement spare Parts

A8V Hydraulic Rexroth Replacement spare Parts

A8V Hydraulic Rexroth Replacement spare Parts

HENGYUHANG Shaft-Port Hydraulic motor BM4(245~800cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM3 4-hole square(100~395cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMRW(50~400cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMPW(50~500cm³/rev)

HENGYUHANG Shaft-Port Hydraulic Brake motor BM2(25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMPH 4-hole square(50~500cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM4 4-hole square(245~800cm³/rev)

HENGYUHANG Shaft-Port Hydraulic Brake motor BM2(25~490cm³/rev).

HENGYUHANG Shaft-Port Hydraulic motor BMPH 4-hole square (50~500cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 6-hole circular(25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 4-hole square(25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 4-hole square (25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 4-hole flange (25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 Two-hole rhombus (25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 Two-hole rhombus (25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 2 Hole flange(25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BM2 two-hole rhombus (25~490cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMM Rhombic flange(8~50cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMM Rhombic flange (8~50cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMM Rhombic flange (8~50cm³/rev)

HENGYUHANG Shaft-Port Hydraulic Wheel motor BM4(245~800cm³/rev)

HENGYUHANG Shaft-Port Hydraulic Wheel motor BM4 Four-hole rhombus(245~800cm³/rev)

HENGYUHANG Shaft-Port Hydraulic Wheel Oilfield motor BM4(245~800cm³/rev)

HENGYUHANG Shaft-Port Hydraulic Oilfield motor BM3(100~395cm³/rev)

HENGYUHANG Port plate hydraulic motor OMS Four-hole rhombus(80~500cm³/rev)

HENGYUHANG Shaft-Port Hydraulic motor BMM Circular flange(8~50cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMS 4-hole square(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic Wheel motor OMS(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMS Rear-mounted flange(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic Two-speed motor OMS(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic Brake drum motor OMS(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMS Six-hole rhombus(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMS No bearing(80~500cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMK Four-hole(110~625cm³/rev)

HENGYUHANG Port-Plate Hydraulic Wheel motor OMK(110~625cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMK No bearing(110~625cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMT 4-hole(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic Wheel motor OMT(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMT No bearing(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic Brake motor OMT(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic Double-cylinder shears motor OMT(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic Sensor motor OMT(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic Two-speed motor OMT(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BMT 2-holes(200~800cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BMT 4-holes(200~800cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BMT No bearing(200~800cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMV 4-holes(310~1250cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor OMV(310~1250cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME Six-hole rhombus(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME Two-hole rhombus(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME Four-hole rhombus(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME2 Two-hole(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME2 Four-hole(195~985cm³/rev)

HENGYUHANG Port-Plate Hydraulic motor BME2(195~985cm³/rev)

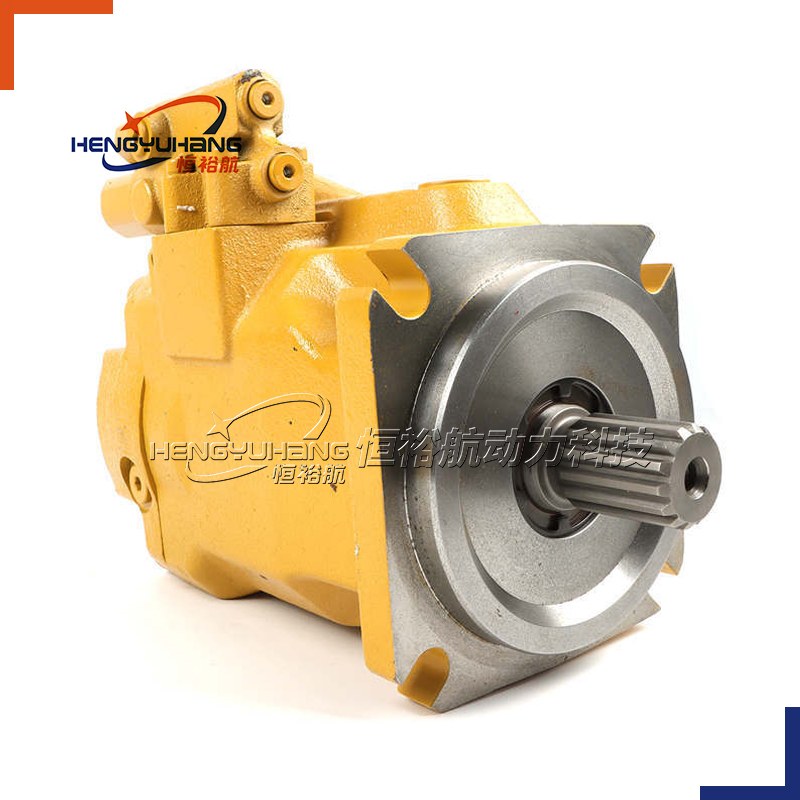

112-6564 1126564 Caterpillar CAT piston pump

161-6634 1616634Caterpillar CAT piston pump

224-6369 2246369 Caterpillar CAT piston pump

235-4108 2354108 Caterpillar CAT piston pump

235-4110 2354110 Caterpillar CAT piston pump

244-2228 2442228 Caterpillar CAT piston pump

245-8998 2458998 Caterpillar CAT piston pump

254-5147 2545147 Caterpillar CAT piston pumps

259-0815 2590815 Caterpillar CAT piston pumps

307-3063 3073063 Caterpillar CAT piston pumps

350-0666 3500666 Caterpillar CAT piston pumps

367-8077 3678077 Caterpillar CAT piston pumps

373-6629 3736629 Caterpillar CAT piston pumps

476-6616 4766616 Caterpillar CAT piston pumps

495-7571 4957571 Caterpillar CAT piston pumps

235-2716 2352716 Caterpillar CAT piston pumps

6E-0838 6E0838 Caterpillar CAT piston pumps

6E-3137 6E3137 Caterpillar CAT piston pumps

9T-1417 9T1417 Caterpillar CAT piston pumps

104-1752 1041752 Caterpillar CAT piston pumps

119-5013 1195013 Caterpillar CAT piston pumps

6E-3139 6E3139 Caterpillar CAT piston pumps

6E-3136 6E3136 Caterpillar CAT piston pumps

146-3685 1463685Caterpillar CAT piston pumps

169-4882 1694882 Caterpillar CAT piston pumps

167-0994 1670994 Caterpillar CAT piston pumps

167-1153 1671153 Caterpillar CAT piston pumps

167-1154 1671154 Caterpillar CAT piston pumps

186-2821 1862821 Caterpillar CAT piston pumps

105-3635 1053635 Caterpillar CAT piston pumps

9T-8346 9T8346 Caterpillar CAT piston pumps

9T-6857 9T6857 Caterpillar CAT piston pumps

6E-5965 6E5965 Caterpillar CAT piston pumps

Parker Hannifin 20/925390 JCB Twin Hydraulic Pumps 6 + 6 CC

Parker Hannifin 20/925687 JCB 524 /527 Twin Hydraulic pumps 21 + 12 CC

Parker Hannifin 209366 6705K Manitou Twin Hydraulic Pumps 41 + 28 CC

20/906300 Genuine Parker / JCB Hydraulic Pump 9 CC/REV 3349112816

332/T4833 Genuine Parker / JCB 524 /527 Twin Hydraulic Pumps 7029521014

6102161M91 Genuine Parker / Massey Ferguson – Terex Twin Hydraulic Pumps 37 + 37 CC

20/925647 Genuine Parker 7029522013/ JCB 527 Twin Hydraulic Pumps

Parker JCB 20/925732 Triple Hydraulic Pumps 40+33+16CC

Parker 14 CC/REV JCB 333/G5393 OEM Hydraulic Gear Pumps

Parker JCB 20/925591 Triple Hydraulic Pumps 36+19+16CC

Parker JCB 919/75002 Hydraulic gear pumps for JCB Loader

Parker JCB 7029122001 OEM Cast Iron Hydraulic Gear Pumps

Parker JCB 7029120077 7029120058 Hydraulic Gear Pumps

Parker JCB 332/G7134 OEM Cast Iron Hydraulic Gear Pumps

Parker JCB 20/925472 OEM Cast Iron Hydraulic Gear Pumps

Parker JCB 332/E6671 hydraulic pumps 45+16 CC/REV

Genuine Parker JCB 334/Y1469 HYDRAULIC PUMPS 33+21CC

Parker JCB 400/A9128 OEM Cast Iron Hydraulic Gear Pumps

PARKER 191-2943 / 7029210001 Hydraulic Gear Motors

Parker Hannifin 332/G6350 JCB 3CX Twin Hydraulic Pumps 33 + 29 CC/REV

Parker Hannifin 20/912800 Hydraulic Pumps 33 + 29 CC/REV

Parker Hannifin 20/903100 Hydraulic gear pumps 33 + 29 CC/REV

Parker Hannifin 20/902900 Hydraulic Pumps 33 + 29 CC/REV

Parker 20/925579 JCB 3CX Twin Hydraulic Gear Pumps 36 + 26 CC/REV

Parker Hannifin 20/925339 JCB 3CX Twin Hydraulic gear Pump 36 + 26 CC/REV

Parker 20/925338 JCB 3CX Hydraulic gear pump 33 + 23 CC/REV

Parker 20/925578 JCB 3CX Hydraulic gear pump 33 + 23 CC/REV

Parker Hannifin 20/925580 JCB 3CX Twin Hydraulic gear Pump 36 + 29 CC/REV

Parker 7029121120 JCB 3CX Hydraulic gear Pump 36 + 26 CC/REV

Parker 7029121120 JCB 3CX Hydraulic gear Pump 36 + 26 CC/REV

Parker 7029120047 JCB 3CX Hydraulic gear Pump 36 + 26 CC/REV

Parker 7029120023 JCB 3CX Hydraulic Gear Pump 36 + 26 CC/REV

Parker Hannifin 7029120006 JCB 3CX Hydraulic Gear Pump 36 + 26 CC/REV

Parker 7029120078 JCB Hydraulic Gear Pump 37 + 33 CC/REV

Parker 7029120005 JCB 3CX Hydraulic Gear Pump 41 + 26 CC/REV

Parker 7029120007 JCB Hydraulic Gear Pump 41 + 26 CC/REV

Parker 20/903200 JCB 3CX Hydraulic gear Pump 41 + 29 CC/REV

Parker 20/911200 JCB 3CX Hydraulic gear Pump 41 + 29 CC/REV

Parker 7441-4071 JCB 3CX Hydraulic gear Pump 41 + 29 CC/REV

Parker 919/71700 JCB Hydraulic gear Pump 41 + 29 CC/REV

Parker 919/66700 JCB Hydraulic gear Pump 33 + 29 CC/REV

Parker 20/925744 JCB 3CX Hydraulic Pump 37 + 37 CC/REV

Parker 7029120052 JCB 3CX Hydraulic Gear Pump 37 + 37 CC/REV

Parker 333/G5392 JCB 3CX Hydraulic Gear Pump 29 + 23 CC/REV

Parker 7029120009 JCB 3CX Hydraulic Gear Pump 29 + 23 CC/REV

Parker 7029120022 JCB Hydraulic Gear Pump 29 + 23 CC/REV

Parker 7029122052 JCB Hydraulic Gear Pump 37 + 29 CC/REV

Parker Terex 3518758M91 Hydraulic Gear Pump 37 + 29 CC/REV

Parker Terex 6101988M92 9306J Hydraulic Gear Pump 37+37 CC/REV

Parker 406827R91 Hydraulic Gear Pump 37 + 29 CC/REV

Parker Terex 6109162M91 Hydraulic gear Pump 37+37 CC/REV

Parker Massey Ferguson Terex Backhoe Loader 7029121002 Hydraulic Gear Pump 37+37 CC/REV

Parker Massey Ferguson Terex 6111152M91 Hydraulic Gear Pump 37+37 CC/REV

Parker 20/925592 JCB 3CX Hydraulic Pump 36+16 CC/REV

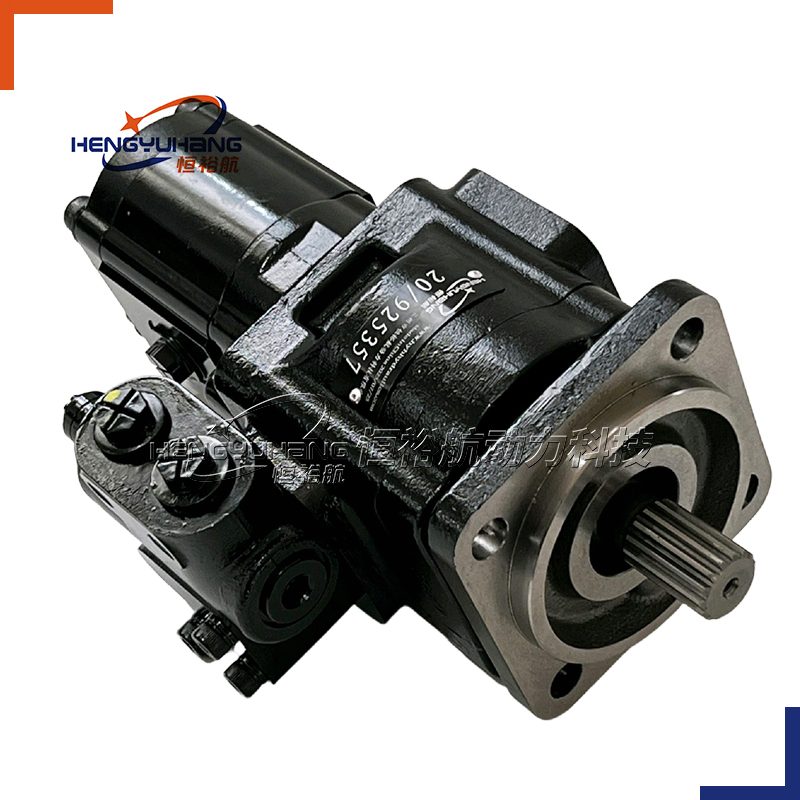

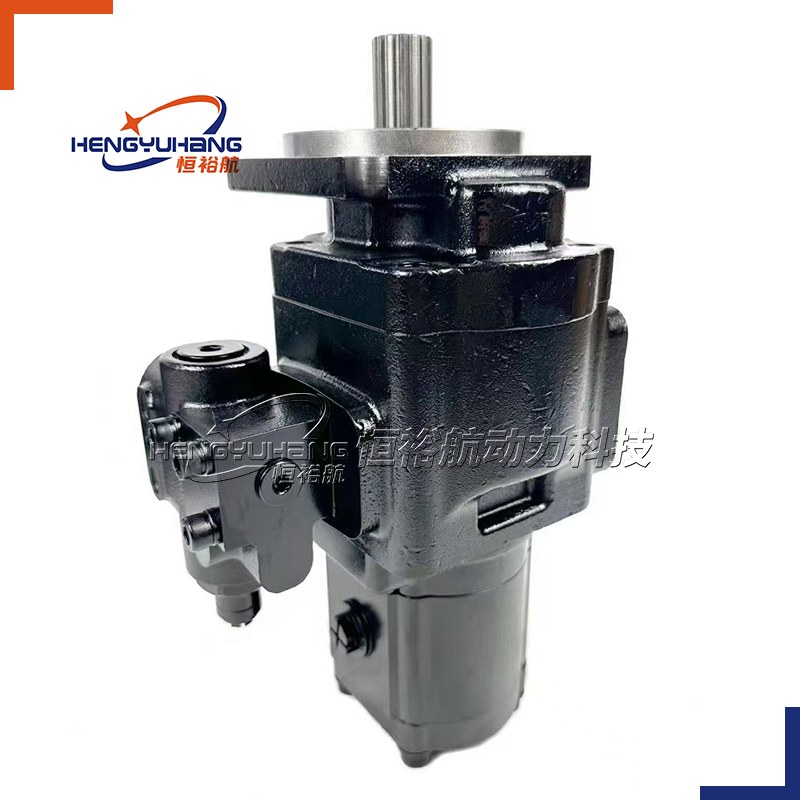

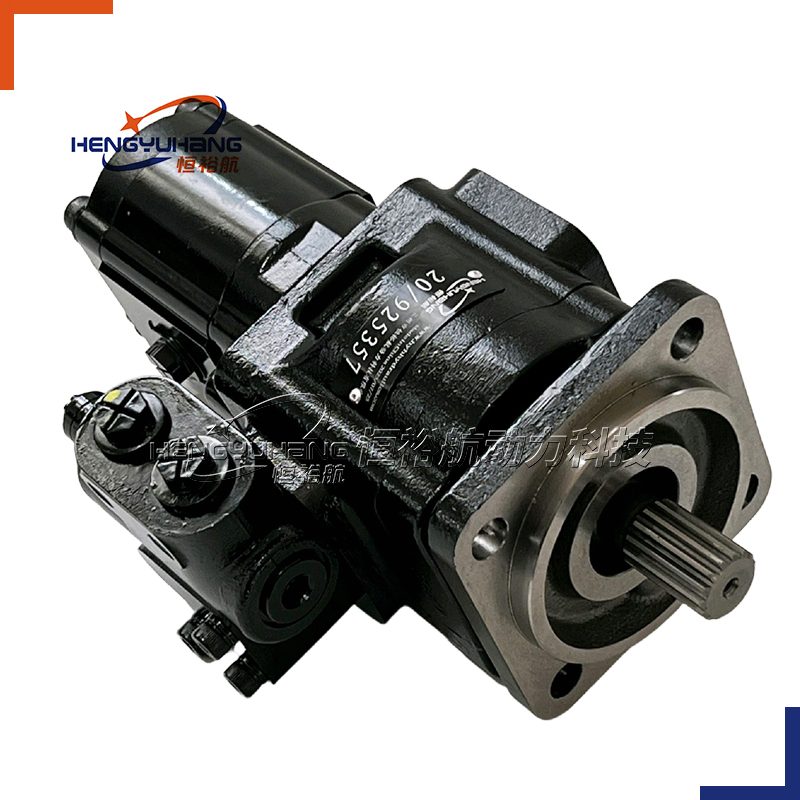

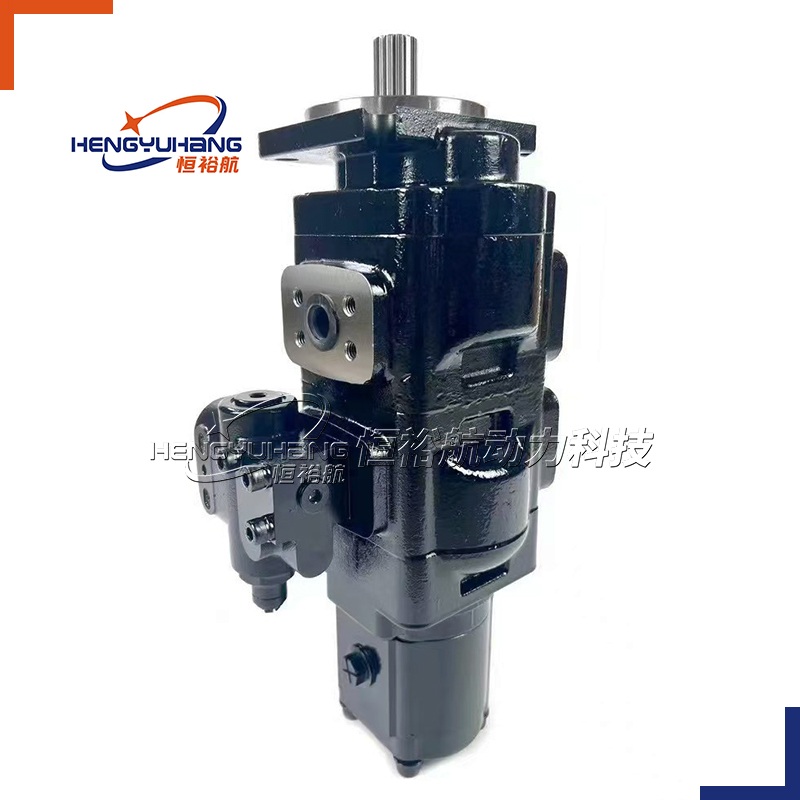

Parker 20/925357 JCB 3CX Hydraulic Gear Pump 36+16 CC/REV

Parker JCB 7049520006 hydraulic gear pump 45+16 CC/REV

Parker JCB 7029522013 Hydraulic Gear Pump 33+13 CC/REV

Parker JCB 20/925613 Triple Hydraulic Gear Pump 40+33+16CC/REV

Parker JCB 7049532007 Triple Hydraulic Gear Pump 40+33+16CC/REV

Parker JCB 20/925588 Triple Hydraulic Gear Pump 29+19+16CC/REV

Parker JCB 20/925356 Triple Hydraulic Gear Pump 29+19+16CC/REV

Parker JCB 20/918500 Triple Hydraulic Gear Pump 29+19+16CC/REV

Parker JCB 7029530002 Triple Hydraulic Gear Pump 29+19+16CC/REV

Parker JCB 20/925355 Triple Hydraulic Gear Pump 36+19+16CC/REV

Parker JCB 20/918300 Triple Hydraulic Gear Pump 36+19+16CC/REV

Parker JCB 333/W2430 Triple Hydraulic Gear Pump 21+12+12CC/REV

Parker JCB gear motor 332/E4402 for JCB 531 -70/ 541-70

Parker JCB gear motor 332/H0538 for JCB 531 -70/ 541-70

Parker JCB gear motor 332/C4268 for JCB 531 -70/ 541-70

Parker JCB gear motor 20/912100 for JCB 531 -70/ 541-70

Parker 7029120025 JCB 3CX Hydraulic Gear Pump 36+29 CC/REV

Parker 7029120048 JCB 3CX Hydraulic gear Pump 36+29 CC/REV

Parker 406763R92 Hydraulic gear Pump 37 + 29 CC/REV

Parker 919/66700 JCB Hydraulic gear Pump 33 + 29 CC/REV

Parker 66513C92 93835C91 Hydraulic Pump for Case/IH CX100, CX70, CX60, CX50, CX80

Parker PGP620 7029521007 3217955410 OEM Hydraulic Gear Pump for drilling machines

Parker PGP620 7049532012 PGP640B0550AE1A4NT4T3C Hydraulic Gear Pump

Parker PGP620 7029530011 PGP620B0500CD1H3*NT5E5C-511B01 Hydraulic Gear Pump

Parker 20/903300 JCB hydraulic gear pumps 33+ 29 CC

Parker 20/907600 JCB Hydraulic Pump 41 + 26 CC

Parker 20/925337 JCB 3CX Hydraulic Pump 29 + 23 CC

Parker 20/925340 JCB 3CX Hydraulic Pump 41 + 26 CC

Parker 20/925341 JCB 3CX Hydraulic Pump 37 + 33 CC

Parker Hannifin 20/925581 JCB 3CX Twin Hydraulic Pump 37 + 33 CC

Parker 20/925586 JCB Hydraulic Pump 29 + 23 CC

Parker 332/F9028 JCB 3CX Hydraulic Gear Pump 33 + 23 CC

Parker Hannifin 332/F9031 JCB 3CX Twin Hydraulic Pumps 37 + 33 CC

Parker Hannifin 332/F9030 JCB 3CX Twin Hydraulic Pumps 36 + 29 CC

Parker 332/F9029 JCB 3CX Twin Hydraulic Pump 36 + 26 CC

Parker 332/F9032 JCB 3CX Hydraulic Pumps 37 + 37 CC

Parker Hannifin 332/G7135 JCB 3CX Twin Hydraulic Pumps 36 + 29 CC

Parker 333/C5234 JCB 3CX Twin Hydraulic Pumps 29 + 23 CC

Parker Hannifin 333/G5390 JCB 3CX Twin Hydraulic Pumps 36 + 29 CC

Parker Hannifin 333/G5391 JCB Twin Hydraulic Pumps 37 + 33 CC

Parker Hannifin 400-E0868 Hydraulic Pumps 33+29 CC

Parker Hannifin 6111153M92 Massey Ferguson Terex Twin Hydraulic Pumps 37 + 37 CC

Parker 20/925366 JCB Hydraulic Pumps 29 + 23 CC

Cast iron External Gear Pump, Group 2PTF multi-pump combination(3~30cm³/rev.)

...

Cast iron External Gear Pump, Group 3PTF multi-pump combination(20~71cm³/rev.)

...

Cast iron External Gear Pump, Group 4PTF multi-pump combination (8~92cm³/rev.)

...

Cast iron External Gear Pump, Group 5PTF multi-pump combination (15~125cm³/rev.)

...

Cast iron External Gear Pump,Group 6PTF multi-pump combination(20~250cm³/rev.)

...

T7BB T7BBS T67CB T67CBW T6CC T6CCW T67DB T67DBW T6DC T6DCW T6DDS T67EB T6EC T6EE T6EES Series Double Vane Pump

...

T67DBB T67DCB T6DCC T67DDBS T6DDCS T67EDB(S) T6EDC(S) Series Three-stage vane pump

...

5050T 50150T 150150T 50250F 150250F Series Fixed Displacement-Double Vane Pump

...

HENGYUHANG Shaft-Port Hydraulic Wheel motor BM4 Four-hole rhombus(245~800cm³/rev)

...

HENGYUHANG Port-Plate Hydraulic Double-cylinder shears motor OMT(195~985cm³/rev)

...

6102161M91 Genuine Parker / Massey Ferguson – Terex Twin Hydraulic Pumps 37 + 37 CC

...

Parker Massey Ferguson Terex Backhoe Loader 7029121002 Hydraulic Gear Pump 37+37 CC/REV

...

Parker 66513C92 93835C91 Hydraulic Pump for Case/IH CX100, CX70, CX60, CX50, CX80

...

Parker PGP620 7029521007 3217955410 OEM Hydraulic Gear Pump for drilling machines

...

Parker Hannifin 6111153M92 Massey Ferguson Terex Twin Hydraulic Pumps 37 + 37 CC

...